DOST Balik Scientist, Unimpressed by 3D Printing Years Ago But Amazed at How It Is Making Waves in Various Industries Now

By: Ella Vanesa L. Lopez

“Ten years ago, sabi ko isip ko, ‘ano naman ang magagawa ng 3D printing na ‘to sa research?’ I was looking at 3D printing from a chemist’s point of view. Eh, para sa mga hobbyist lang ito, but look at what happened now. May AMCen tayo at marami na ring papers ang napa-publish sa 3D printing.”

Dr. Eugene Caldona mentioned this fond memory during his presentation on "Additive Manufacturing of Engineering and High-Performance Polymeric Materials" on July 13, 2023. The DOST Balik Scientist shared his perception then of additive manufacturing (AM) impacting product development far-off from reality.

Official poster for Dr. Eugene Caldona’s talk on “Additive Manufacturing of Engineering and High-Performance Polymeric Materials.”

Façade of the Advanced Manufacturing Center (AMCen) of the DOST-MIRDC, the largest 3D printing facility in the country.

AM or 3D printing technology was first introduced in the 1980s, and has significantly advanced in recent years. 3D printing is now being utilized to create simple do-it-yourself items as well as large-scale structures such as a house or a building. This just clearly shows that there is no limit to technology.

Dr. Caldona explained all about the different high-performance materials that are now being used in 3D printing during his talk.

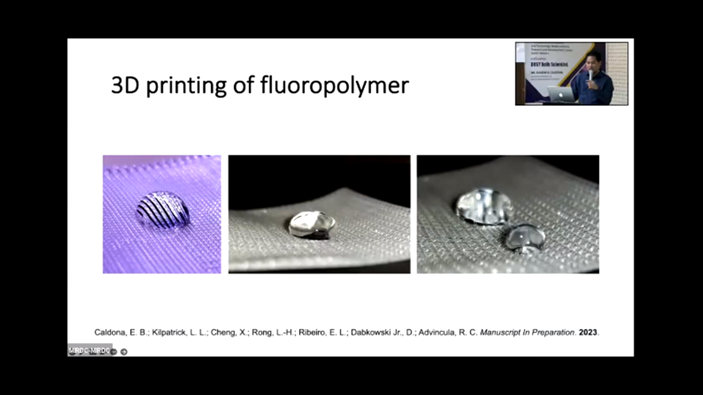

Dr. Caldona discussed polymers and the rising trend of AM across the globe. Further, he talked about the challenges and tips on how to effectively 3D print high-performance materials, which include polyetheretherketone (PEEK), polyphenylene sulfide (PPS), Kevlar, polypropylene, fluoropolymer, and Epoxy-based materials.

The Philippines has ventured into AM to be at par with its ASEAN neighbors, who have long been implementing this technology. A manifestation of the country’s venture into AM is the Advanced Manufacturing Center (AMCen) of the Department of Science and Technology – Metals Industry Research and Development Center (DOST-MIRDC). The AMCen embarks on initiatives to enhance the aerospace, defense, biomedical, healthcare, and automotive industries, among others, through 3D printing.

Dr. Caldona expounded on the different polymers that are currently being used by the 3D printing industry, some of which are also offered by the AMCen. In AMCen, clients have a variety of materials to choose from depending on their requirements, such as (1) Standard Polymers: polymethylmethacrylate (PMMA) standards, polyvinyl chloride (PVC), polystyrene (PS), polyethylene terephthalate (PET, PETE, PETG), acrylonitrile butadiene styrene (ABS), and polypropylene (PP); (2) Engineering Polymers: polycarbonate (PC), thermoplastic polyurethane (TPU), and polyamides (PA) or nylon; and (3) High-Performance Polymers: polyethyleneimine (PEI), and polyetherketone (PEEK).

Some of the different additive manufacturing technologies that are available at the Advanced Manufacturing Center (AMCen).

According to Dr. Caldona, the rapid and systematic fabrication approach offered by this cutting-edge technology is what commonly appeals to people. However, others might not realize that 3D printing will not only accelerate the product development phase but also improve supply chain efficiency.

The continuous rise of the use of 3D printing for research, innovation, and manufacturing is now very obvious and very different from what Dr. Caldona perceived many years ago. Soon, more people are expected to create things differently from the conventional methods that we are used to.

The recently concluded seminar is the fourth in the seminar series by Dr. Caldona for the DOST Balik Scientist Program (DOST-BSP). The DOST-BSP encourages Filipino experts abroad to return home and impart their expertise in order to foster the advancement of science, technology, and innovation in the country. Dr. Caldona’s engagement with the DOST-MIRDC as a DOST Balik Scientist is focused on the Center’s Surface Engineering R&D Program.