DOST Balik Scientist Dr. Caldona’s Works Focuses on Corrosion Science; Shares to Fellow Researchers

by Faith P. Macatangay

Dr. Eugene B. Caldona’s stint as a DOST Balik Scientist may have been short, but truly very sweet. Thanks to the series of webinars he conducted, external participants, as well as the researchers at the DOST-MIRDC, learned much about surface engineering.

Dr. Caldona brought his laboratory closer to Filipinos as he shared his group’s research projects and activities during the last of the five-part seminar series entitled ‘High Performance Thermosets, Semi-Fluorinated Polymers, Thin Films, Composite Coatings, and 3D Printed Materials,’ held on July 17, 2023.

Dr. Caldona gave a brief background on the State of Dakota in the United States of America, the North Dakota State University, and its Department of Coatings and Polymeric Materials, where he is currently affiliated as an Assistant Professor. He also shared about his research group that specializes in the fabrication of advanced protective coatings, the development of new groups of coating materials and corrosion-preventing materials, and the utility of electrochemical approaches to evaluate the protection efficiencies of coating materials.

By definition, corrosion is the deterioration of a substance of its properties as a result of an undesirable reaction with the environment. Dr. Caldona emphasized that “the damage we encounter from corrosion can be minimized by using a coating that can function as a layer of physical barrier.” According to Dr. Caldona, this coating serves as a protection by slowing down the transport of aggressive substances that harm and damage metal surfaces.”

In his presentation, he enumerated the following coatings to minimize corrosion: organic polymer coatings, stand-alone polymer barrier coatings, and additively manufactured coatings.

Organic polymer coatings are the most widely used corrosion barriers due to ease of application, high-performing capabilities, and effective functionalities. Adding micro and nano-size fillers can further enhance the overall coating performance. Their surface may also be roughened to improve the anti-wetting properties of coatings.

Stand-alone polymer barrier coatings are also utilized because of their simplicity and ease of preparation. They are proven effective as they act as an insulating layer that blocks electron transfer between the metal and corrosive medium to prevent the electrochemical oxidation process.

Additive manufacturing or 3D printing was also applied for coating purposes. 3D printing in coating preparation is beneficial mainly due to its automation and digital design availability. The 3D printing approach helps solve failures in many coating materials.

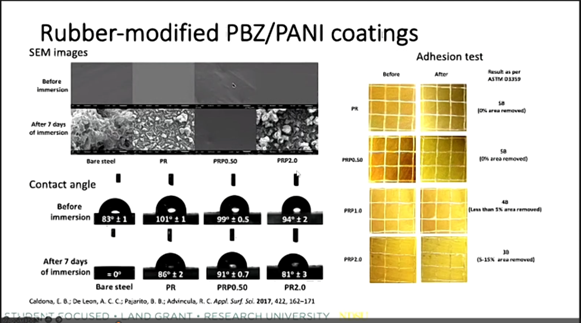

A slide presented by Dr. Caldona shows the results of a study about rubber-modified polybenzoxazine-based (PBZ)/ polyaniline (PANI)coatings. PBZ is an example of an organic polymer coating.

Meanwhile, corrosion inhibitors are different from coatings. These compounds are added in minimal quantity to a corrosive medium to slow down the corrosion rate - their inhibiting abilities lie in their molecular structure and ability to absorb and form a protection barrier across the metallic surface. Organic compounds that contain combinations of sulfur, oxygen, phosphorus, nitrogen, aromatic rings, and multiple bonds have been shown to function effectively as corrosion inhibitors.

Superhydrophobic surfaces are applied for the best possible protection of metals from being rotten. They stand out due to their anti-wettability property. Only two requirements are required to achieve super hydrophilicity – surface roughness on micro and nanoscale and low surface energy materials.

“[In] Every research that deals with coatings, [it] is important to consider the effect of damages on the coating and integrity and performance during their intended use,” Dr. Caldona noted.

The resource person, Dr. Eugene B. Caldona, discusses to the onsite and online participants.

To know more about the research and development activities and the trainings and seminar offerings of the Center, visit the DOST-MIRDC’s website and Facebook page.