Adult Ventilator Developed by DOST-MIRDC Set to Undergo Clinical Trial

By: Zalda R. Gayahan

The clinical trial for the OstreaVent II is the next step for this locally designed and developed ventilator for adults. It will be done at the Philippine General Hospital. At the moment, the team who will conduct the clinical trial is just waiting for the appropriate time when the PGH facility and medical workers are not too overwhelmed with Covid-19 cases.

Taking the lead in this research and development is the DOST-Metals Industry Research and Development Center in partnership with the Breath of Life Foundation, Inc.

OstreaVent II used the technology of its predecessor, the OstreaVent I, which is for infant use only. The project team embarked in R&D to design the OstreaVent II so that it will have the following features: it can be for both infant and adult use; it is both pressure- and volume controlled; it has a feature to measure tidal volume; and it has bacterial and viral filters.

After the completion of the OstreaVent II prototype in June 2020, it was subjected to a medical Device Inspection by the MedEquip. The University of the Philippines Manila Research Ethics Board (UPMREB) approved its Safety Trial Protocol in July 2020. In March this year, the OstreaVent II’s Medical Device Inspection Certificate was issued by the MedEquip and the Food and Drug Authority (FDA) granted the Certificate of Medical Device Listing to signify that the OstreaVent II may proceed with the clinical trial.

In April 2021, the Breath of Life Foundation formed the team that will implement the clinical trial for one month which, based on the Safety Trial Protocol, will involve 10 non-Covidpatients. The team will be headed by Dr. Manuel Jorge who heads the team of Adult Pulmonology Fellows at the UP-Philippine General Hospital.

After the clinical trial, five units of the OstreaVent II will be produced: four will be used for field testing, one will be used for further design improvements. If all activities will proceed as planned, licensing and production may begin by November this year.

Activities to Improve LRT-1 Services to Go Full Swing in May

By: Zalda R. Gayahan

April 21, 2021 – The Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC) entered into a partnership with the Light Rail Manila Corporation (LRMC) with the shared goal of improving the services of the Light Rail Transit – Line 1 (LRT-1).

The LRMC sought the expertise of the DOST-MIRDC in the areas of fabrication of obsolete or difficult-to-source spare parts and conduct of structural repairs of light rail vehicles (LRVs). Even before the signing of the MOU, the LRMC and the DOST-MIRDC have already began the inspection of the LRVs. After the initial inspections, the DOST-MIRDC conducted preliminary analysis which gave the MIRDC team a better perspective of the technological interventions needed. Succeeding inspections are set to be conducted beginning in May, when hopefully the NCR will be placed in a less stringent community quarantine.

The LRMC expressed excitement and optimism in the partnership. The LRMC shared that they tried to look for a partner, either local or foreign, who will be able to help them address the technical issues with the LRVs. ‘We looked everywhere,’ says LRMC Chief Operating Officer, Enrico Benipayo, ‘but unfortunately…the interest of foreign companies is not really there.’

Engr. Robert O. Dizon, DOST-MIRDC’s Executive Director, imparted the agency’s appreciation of the partnership with the LRMC. Director Dizon said that the DOST-MIRDC’s services are open to the LRMC, to help create improvements for the LRT-1 and also to pursue the Center’s mandate of assisting the local metals, engineering, and allied industries. ‘We are optimistic that the establishment of a competitive railway industry will be one of the outcomes of this partnership,’ Dir. Dizon added.

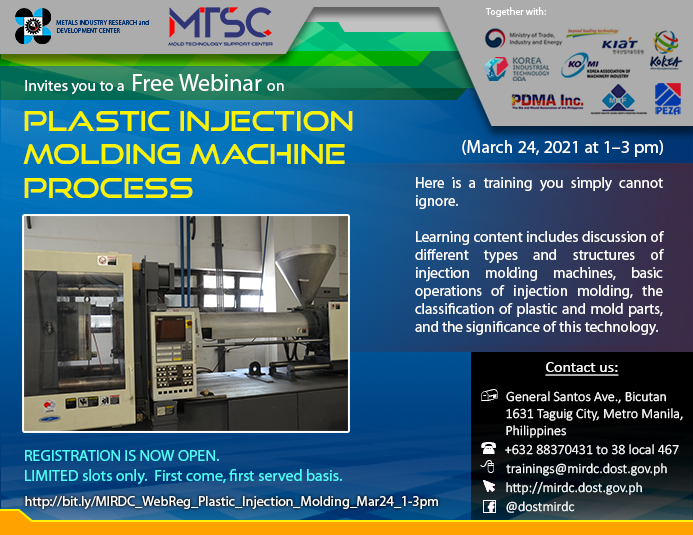

To register to this webinar, please click on this link: http://bit.ly/MIRDC_WebReg_Plastic_Injection_Molding_Mar24_1-3pm

Here is a training you simply cannot ignore.

Learning content includes discussion of different types and structures of injection molding machines, basic operations of injection molding, the classification of plastic and mold parts, and the significance of this technology.

Contact us:

Tel. No. +63 (02)8837-0431 to 38 local 467

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Maker of Rain Boots Benefits from Services of the DOST-MIRDCMaker of Rain Boots Benefits from Services of the DOST-MIRDC

By: Jim Patrick S.D. Erispe

Boscolo Mfg. Corp., a privately-owned company based in Pasig City, is the maker of Spartan rain boots. Spartan is known in the market as quality, yet affordable, rubber boots.

Boscolo Mfg. Corp., a privately-owned company based in Pasig City, is the maker of Spartan rain boots. Spartan is known in the market as quality, yet affordable, rubber boots.

At the time when the country was brought under community quarantine, Boscolo Mfg. Corp. sought the services of the Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC) to help them rehabilitate their 24-piece aluminum boots mold. These are imported molds estimated to be 5 years old already.

As it is the DOST-MIRDC’s mandate to provide assistance to the industry, the rehabilitation assistance the Center extended to the company involved the restoration of the molds of Boscolo Mfg. Corp. Using mold technology, CNC machines, and laser welding, the DOST-MIRDC attended to the task of polishing the built-up portions of the molds. Also, the Center prepared a program that incorporated important branding details to the mold – it now contains the Spartan Armor Viking and helmet logo.

The quality of mass-produced goods is largely influenced by the quality of well-maintained molds. The rehabilitation of the boots molds of Boscolo Mfg. Corp. and the inclusion of the logo in the design of the molds are remarkable investment decisions. The polished molds now help in producing great-looking boots, and the logo is a smart marketing strategy.

The rehabilitation process of the molds started in July of 2020 and was completed in December 2020.

The company is poised to engage in profitable business as boots come in handy for many Filipinos in different walks of life.

The DOST-MIRDC entertains inquiries related to the use of metalworking technologies for the benefit of businesses across various industries.

Importance of Science and Technology Apply to All, Even to Electric Poles

By: Jim Patrick S.D. Erispe

Electric posts have welded metals that provide added strength. That is, if the metals are checked and tested regularly.

Electric poles along Quirino Highway in San Jose del Monte, Bulacan had their ‘check-up’ done in 2020.

The check-up conducted is called the Liquid Penetrant Testing, which focused on welded joints of the poles.

For the sake of raising the public’s awareness on how science and technology find application in all that we do, the Liquid Penetrant Testing is a kind of non-destructive test (NDT). It is a test that does not break apart or destroys a sample.

It is a test method that is very effective in detecting porosity, cracks, fractures, laps, seams, and other flaws which may be caused by fatigue, impact, quenching, machining, grinding, forging, bursts, shrinkage, or overload.

If left untested, the public has no way of determining the integrity of various structures that we commonly see and use daily.

The test conducted will show the actual condition of an electrical pole. Results will determine if the electrical pole can withstand earthquakes and typhoons, absorb energies from impacts of vehicles in accidents, and carry heavy electrical or internet cables.

The test generally offers safety to the general public.

The Liquid Penetrant Testing is a service offered by the Non-Destructive Laboratory of the Department of Science and Technology – Metals Industry Research and Development Center.

This is just one of the many ways by which science and technology find application in the everyday life of each Filipino.