Challenges of the Philippine Metal Casting Industry: Metal Casting Companies Up Close and Personal with DOST-MIRDC

By James Bernard Herrera

The metal casting industry is said to be a cornerstone of manufacturing industries worldwide. It is involved in the various sectors that make a country’s economy thrive, such as agriculture, transportation, and defense sectors. However, in the Philippines, the metal casting industry has been experiencing a constant decline over the last few decades, which directs us to this question: what are the causes of this decline?

The Department of Science and Technology - Metals Industry Research and Development Center (DOST-MIRDC) gathered local metal casting companies for a focus group discussion (FGD) on September 23, 2024, at La Breza Hotel, Quezon City. The event was part of the Center’s industry study titled “Local Metal Casting Industry Thriving Despite Challenges,” to verify the study’s findings as it nears completion.

The study focuses on why the metal casting industry, once robust, has become a declining industry in the Philippines. From hundreds of local foundries operating in the 1970s, the number has dwindled to just 68 foundries.

During the FGD, the team presented the study findings, where participants also provided feedback and verification.

Industry players showing keen interest in the findings being presented by Ms. Kathlyn Kai Negado.

Money factor. The first and most pressing challenge identified was financial. Many companies have experienced a shrinking market share, which they attributed largely to the influx of imported cast products. As one participant noted, “The local market is not just being penetrated by imports, it’s already dominated by them.”

Machine and method factors. The financial strain also ties into the challenges around machines and methods. Many companies are reluctant to invest in modern technology, fearing that the uncertain market demand will not justify the cost. Most foundries now operate on a jobbing basis, which makes investing in technology and capability upgrades too risky a business move. One participant shared their company’s first-hand experience: one of their customers opted to import metal cast products rather than commission their foundry for production.

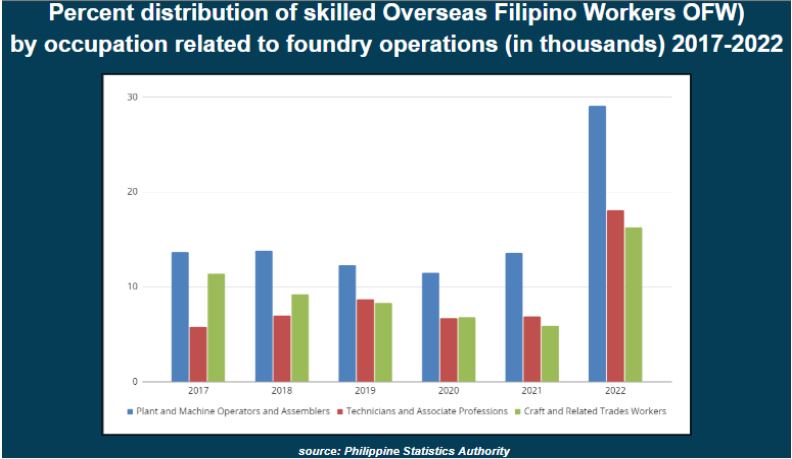

Manpower factor. The next major challenge is manpower. The metal casting industry has been grappling with brain drain for over a decade. Data from the Philippine Statistics Authority (PSA) shows that thousands of skilled workers in related fields have gone abroad, leaving a significant shortage of talent in the local industry.

Many companies have been forced to recruit and train workers with no prior knowledge or experience. Some participants confirmed this statement and even mentioned that they actively search for potential employees in provincial areas, as many urban-based young workers view foundry jobs as “dirty and unappealing”—a sentiment widely echoed during the discussion.

Materials factor. Material sourcing also presents a challenge. Most local foundries rely on imported raw materials, such as silica sand and foundry coke. The import taxes on these materials lead to increased production costs, forcing companies to raise their prices to remain viable, further hindering the industry's marketability.

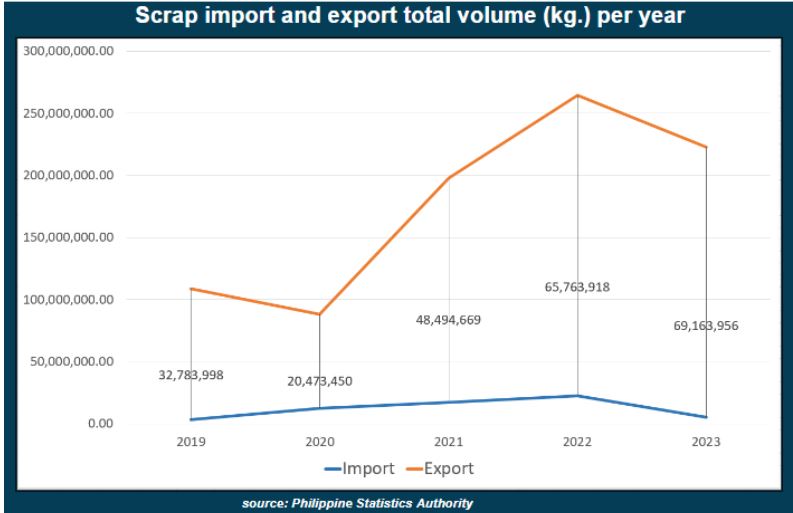

Aside from these imported materials, procuring locally-available scrap is also part of the challenge due to its price being unregulated at present by any government entity. It is also discussed that the Philippines exports high volumes of scrap material in kilograms over the last five years, where Bangladesh is found to be the top client. During the discussion, industry players mentioned that the price of local scrap is currently being dictated by the purchasing rates of steel companies, making the price of scrap metal very erratic within the local market.

As the FGD wrapped up, Industry Consultant Engr. Napoleon Tanganco expressed optimism: “I believe the current number of existing companies will stabilize, as most of the remaining ones are large enterprises.” However, while larger companies may continue to survive, smaller ones will likely continue to struggle unless significant changes are made. This is where DOST-MIRDC’s role becomes crucial. The study team gathered additional feedback during the FGD, which will be incorporated into the industry study.

Engr. Napoleon Tanganco sharing his insights during the discussion

Moving forward, the study team will consult with DOST-MIRDC experts and management to finalize recommendations. The goal is to revitalize the local metal casting industry and significantly contribute to the country’s economic development. The study’s findings and recommendations are scheduled to be presented to the Center’s officials and Governing Council by the end of 2024.