DOST-Developed Mass Transportation Alternatives Eyed by DOTr as Potential Technology-Based Solution to Easing Passenger Transfers within NAIA Terminals

By: Zalda R. Gayahan

Bicutan, Taguig City - The Automated Guideway Transit (AGT) System is being considered as a means to connect terminals 1 to 4 of the Ninoy Aquino International Airport (NAIA).

Department of Science and Technology (DOST) Secretary Renato U. Solidum welcomed Department of Transportation Secretary Jaime J. Bautista as the two department heads signed a Memorandum of Agreement regarding the partnership of the DOTr with the DOST, through the Electronics Product Development Center (EPDC).

Present to witness the MOA signing was Engr. Robert O. Dizon, Executive Director of the DOST-Metals Industry Research and Development Center (DOST-MIRDC), who presented to the DOTr Secretary alternative mass transportation technologies developed by the Center: the Automated Guideway Transit (AGT) System; Hybrid Electric Road Train (HERT), and Hybrid Electric Train (HET).

Mass transportation alternatives developed by the DOST-MIRDC: L - Automated Guideway Transit (AGT), center - Hybrid Electric Road Train (HERT), and R - Hybrid Electric Train

DOTr Secretary Bautista immediately saw the benefits of adopting these home-grown mass transportation technologies, particularly the AGT which offers the best solution to make transfers to various terminals of the NAIA easy and convenient.

DOTr Secretary Jaime J. Bautista (L), DOST Secretary Renato U. Solidum (center), and DOST-MIRDC Executive Director Engr. Robert O. Dizon, view and discuss the possibility of utilizing DOST-developed mass transportation technologies such as the Automated Guideway Transit (AGT) to connect Terminals 1 to 4 of the NAIA.

Aside from the AGT, the HERT is also seen as a possible alternative to buses for the EDSA Carousel and the articulated buses for the proposed Bus Rapid Transit (BRT) systems in the country.

To formalize these concepts, the DOTr and DOST agreed to work on the preparation of a project proposal for further consideration by the two agencies. Should this proposal later progress and be implemented as a joint project, the public can expect to have safer and more convenient public transportation.

Revival of Metalcasting Industry in Region III pushed by DOST through the Metals and Engineering Innovation Center

by: Ella Vanesa L. Lopez

Amidst the closing down of several foundry shops in the country, the Department of Science and Technology (DOST) drives for the revival of the metalcasting industry.

The DOST - Metals Industry Research and Development Center (DOST-MIRDC), in collaboration with the DOST-Philippine Council for Industry, Energy and Emerging Technology Research and Development (DOST-PCIEERD) and the DOST Regional Offices, is currently implementing a project entitled “Establishment of Metals and Engineering Innovation Center (MEIC) in CAR, Regions I, II, III, and X.” The MEIC project aims to strengthen the research and development outputs in the countryside by procuring industry-grade types of machinery and increasing the pool of experts in the field of metals and engineering through trainings, seminars, and workshops.

In its efforts to further capacitate the faculties and personnel of the MEIC host universities, the DOST-MIRDC partnered with private companies to provide them with an Industry Immersion Program. With the help of this program, faculty members will become more aware of the demands of the industry, have a deeper understanding of those demands, and be better able to apply what they learn to their work as instructors, researchers, and future consultants.

The Nueva Ecija University of Science and Technology (NEUST), Sumacab Campus, is located in Cabanatuan City and serves as the host institution for the MEIC in Region III. The NEUST-MEIC, whose focus is on metal casting, underwent a two-week immersion program on November 7–18, 2022. Three renowned foundries in Valenzuela—Acetech Metal Industries Corporation, Maysan Casting Corporation, and Ichivan Metal Casting—as well as Metals Engineering Resources Corporation (METERCOR), a well-known foundry in Sto. Tomas, Batangas, accommodated the NEUST participants.

Mark John M. dela Cruz and Jaymart O. Jose of NEUST undergo immersion inMark John M. dela Cruz and Jaymart O. Jose of NEUST undergo immersion inAcetech Metal Industries Corp.

The foundries introduced their unique techniques and best practices to the NEUST participants. Tried and tested for so many years by these foundry men, the participants were motivated to embrace, alter, and improve these learnings to fit into the current practices of the NEUST-MEIC. Other skills were also developed in the participants, such as core making, patternmaking, molding, and melting.

NEUST-MEIC participants’ learning about Floor Molding

The DOST-MIRDC is optimistic that this program will not only benefit the participants and their university but also the metalcasting industry in Region III by leveraging the knowledge and skills of our NEUST-MEIC researchers and consultants.

DOST-MIRDC Technologies Featured at the 2022 NSTW Celebration Technical Forums and Exhibits

by Kai H. Negado

Pasay City, Metro Manila - This year’s National Science and Technology Week (NSTW) celebration exhibits featured technologies consistent with the theme ‘Agham at Teknolohiya: Kabalikat sa Maunlad at Matatag na Kinabukasan.’

The Advanced Manufacturing Center (AMCEN) and the Advanced Mechatronics, Robotics, and Industrial Automation Laboratory (AMERIAL) are facilities of the DOST-Metals Industry Research and Development Center featured under Cluster 4: Job Generation, Livable and Sustainable Communities, and Digital Transformation, along with exhibits from the DOST Regional Offices and DOST Research and Development Institutes.

AMCen and AMERIAL were chosen as part of the technology showcase area under the category of digital transformation. These facilities offer Industry 4.0 technologies to increase innovation and boost levels of productivity, contributing to our local manufacturing industries’ digital transformation by using intelligent machines and automating manufacturing and supply chain processes.

For our local businesses to become competitive here in the country and possibly with counterparts abroad, the DOST, through the DOST-MIRDC, aims to make AMCen and AMERIAL technologies available to all businesses in the metro and in the countryside. The said facilities are meant to address the challenges faced by our partners in the industry, especially our MSMEs.

Both AMCEN and AMERIAL are facilities or centers which offer services that aim to increase the country’s technical readiness, business sophistication, and innovation to drive local industries to higher levels of productivity and competitiveness through emerging technologies namely:

- Additive manufacturing or 3D printing

- Mechatronics

- Robotics

- Industrial automation

Two of the 3D printing technologies available in the AMCEN and the AMERIAL’s 6-axis Collaborative Robot were displayed during the week-long exhibits, sparking interest and possible collaboration not just from industry players present during the exhibit, but also visitors from the academe - administrators, teachers, and students alike.

President Marcos, Jr. at the AMCen exhibit during the 2022 NSTW

AMERIAL’s robotic arm at work during the 2022 NSTW Exhibits

2022 NSTW Celebration Technical Forums

Day four and five of the 2022 NSTW celebration featured technical forums from the DOST-MIRDC, all of which were centered around technologies and facilities that are readily available to be utilized by clients who require services offered by the DOST-MIRDC. Featured in the forums are the AMCEN, Building a Universal Mount for Heavy Barrel Automated Weapon Integration (BUHAWI) Project, and the AMERIAL, Mold Technology Solution Center (MTSC), and the Metals and Engineering Innovation Centers (MEICs).

Engr. Padaca III of DOST-MIRDC’s AMCen during the 2022 NSTW Technical Forum.

Attendees during the AMCen presentation at the 2022 NSTW Technical Forum

Experts from the DOST-MIRDC presented their respective projects to the forum attendees. For AMCEN, Engr. Jose Bernardo L. Padaca III discussed how the Center may provide product development support to different sectors by introducing additive manufacturing technologies to boost the country’s innovation landscape. Engr. Padaca says additive manufacturing or 3D printing ‘can have a very big impact or be a very big help in supporting these industries.’ With AMCen, he explained that ‘the goal is to support local industries… these priority industries for domestic and export markets’.

DOST-MIRDC Deputy Executive Director for Technical Services Engr. Puerto discussing Project BUHAWI to the crowd during the 2022 NSTW Technical Forum.

Next to present was DOST-MIRDC’s Deputy Executive Director and project leader Engr. Jonathan Q. Puerto, who showcased the BUHAWI technology by discussing Filipino capabilities to locally develop and produce technologies that are in support of the Department of National Defense’s (DND) Self-Reliant Defense Posture (SRDP) Program. The successful testing and technology transfer of the BUHAWI were among the highlights of the presentation. Attendees expressed interest by asking additional questions to Engr. Puerto on the capabilities of our locally produced technologies and the capacities of our own Filipino engineers.

Engr. Libao of DOST-MIRDC presenting AMERIAL technologies and its applications during the 2022 NSTW Technical Forum

For the afternoon forum, Engr. Franz Joseph D. Libao discussed the DOST-MIRDC’s AMERIAL, a state-of-the-art facility that offers services to our local industries to increase their levels of productivity using the latest technologies for mechatronics, robotics, and automation. Engr. Libao discussed the importance of these technologies and the Industry 4.0 readiness of the country’s local enterprises.

Engr. Libao of DOST-MIRDC answering the attendees’ questions regarding the AMERIAL during the 2022 NSTW Technical Forum.

During the forum, the main question raised by Engr. Libao was ‘Are the Philippine MSMEs ready for Industry 4.0?’ Based on the AMERIAL team’s research, he explained that ‘Medyo malayo pa. Marami tayong kailangan gawin at pagdaaanan para magamit talaga natin, para ma-take advantage natin ang mga benefits ng Industry 4.0.’ To end his presentation, he offered the Laboratory’s services to help address the readiness of our local enterprises and to kick-start their use of Industry 4.0 technologies.

The last day of the 2022 NSTW celebration saw technical forums from the DOST-MIRDC’s MTSC and the MEICs. Engr. Francisco C. Dime and Mr. Osric Primo Bern A. Quibot were the ones to present the MTSC and MEICs, respectively.

Engr. Dime of DOST-MIRDC discusses how the MTSC can help local manufacturers during the 2022 NSTW Technical Forum.

First to present was Engr. Dime, highlighting the MTSC’s capabilities in addressing the needed services for mold-related projects. He also explained the various equipment and software currently available for use at the MTSC, and the Center’s accomplishments even with the challenges brought about by the COVID-19 pandemic.

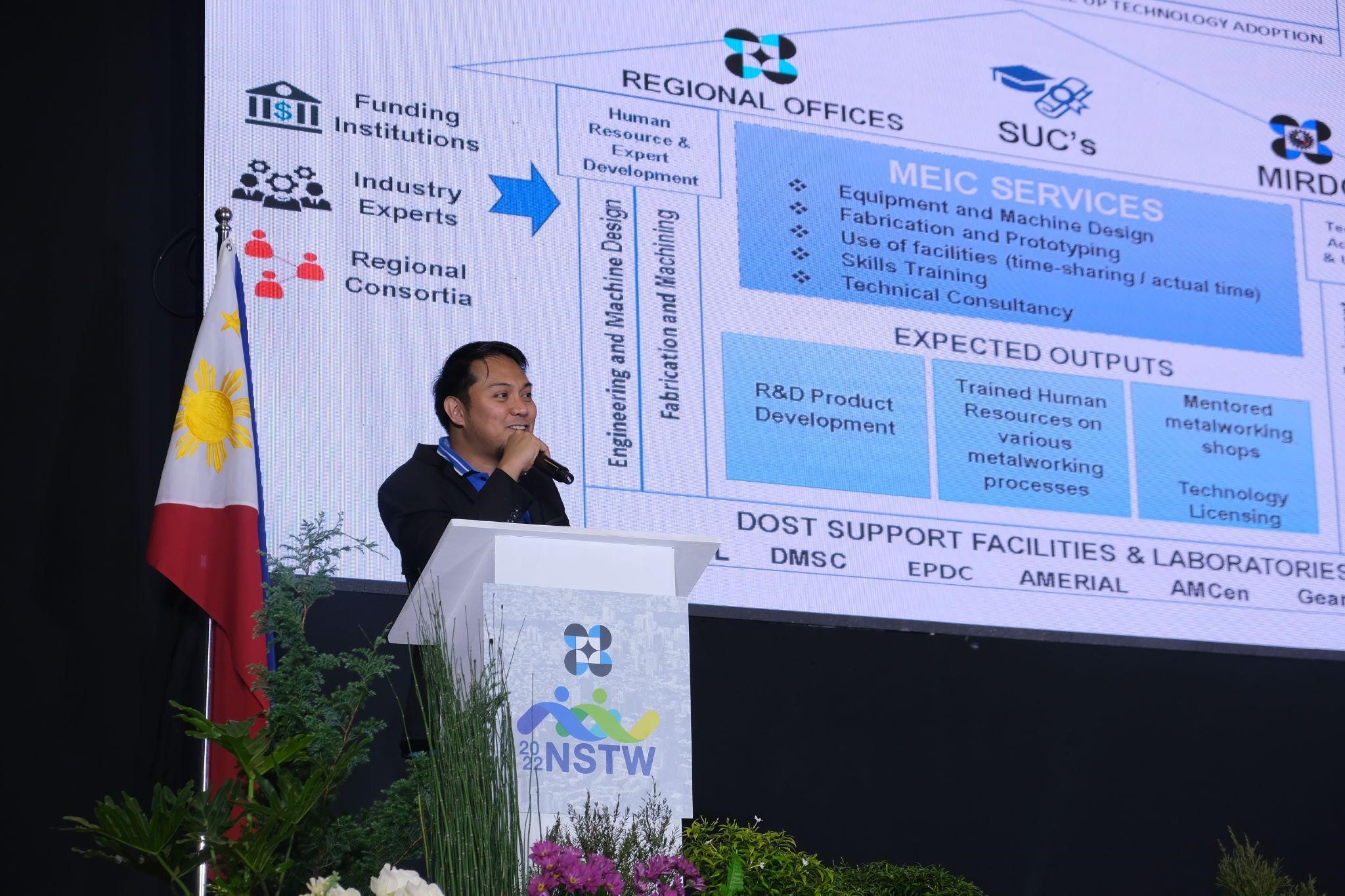

Mr. Quibot of DOST-MIRDC presents the MEICs and how these will help local MSMEs during the 2022 NSTW Technical Forum.

The last technical forum conducted during the 2022 NSTW celebration was presented by Mr. Quibot of the DOST-MIRDC. Mr. Quibot discussed that the MEICs were established as a way to achieve the Center’s vision of a more competitive metals, engineering, and allied industries for the whole country. Mr. Quibot further explained that the MEICs, in partnership with both academic institutions and the industry, were established to add new technical capabilities and sustain the growth of innovation in the different regions of the country.

DOST-MIRDC saw the 2022 NSTW celebration’s exhibits and technical forums as an opportunity to showcase its technologies and services to its various stakeholders, especially the general public. As the event’s official song says, ‘Science is for you and me. Atin ‘to!’ – a testament to how the DOST, through its various line agencies, is committed to realizing its goal of bringing science, technology, and innovation much closer to the people.

R&D and Innovation Capacity of Region III to be Enhanced by DOST through Metals and Engineering Innovation Center (MEIC)

By: Ella Vanesa L. Lopez

Cabanatuan City, Nueva Ecija - “Kaya po kami nandito ngayon para malaman namin kung ano pa ang mga kailangan namin gawin para sa industry,” said Ms. Stephanie Ann B. David, Science Research Specialist II of the DOST-Philippine Council for Industry, Energy, and Emerging Technology Research and Development (DOST-PCIEERD).Cabanatuan City, Nueva Ecija - “Kaya po kami nandito ngayon para malaman namin kung ano pa ang mga kailangan namin gawin para sa industry,” said Ms. Stephanie Ann B. David, Science Research Specialist II of the DOST-Philippine Council for Industry, Energy, and Emerging Technology Research and Development (DOST-PCIEERD).DOST-PCIEERD, in cooperation with DOST Regional Office No. III, conducted an industry consultation with the local metals and engineering (M&E) industry to assess the industry’s needs last December 7, 2022, at the Nueva Ecija University of Science and Technology (NEUST) Sumacab, Campus.

Attendees of the M&E Sector Industry Consultation in Region III

Present at the event are personnel from PCIEERD, DOST-Regional Office No. III, DOST-Provincial Science and Technology Offices (PSTO), DOST-Metals Industry Research and Development Center (DOST-MIRDC), members of the academe, and various M&E industry key players and stakeholders.Present at the event are personnel from PCIEERD, DOST-Regional Office No. III, DOST-Provincial Science and Technology Offices (PSTO), DOST-Metals Industry Research and Development Center (DOST-MIRDC), members of the academe, and various M&E industry key players and stakeholders.Ms. David gave a rundown of the recent DOST initiatives aimed to further develop the R&D and innovation capabilities of the country. Among them are the DOST-MIRDC’s Metals andEngineering Innovation Centers (MEICs), as well as the Universal Mount for Heavy Barrel Automated Weapon Integration, or BUHAWI project. She explained that the Council is nowreviewing its priority programs, which is why they have been holding these industry consultations.

Engr. Ma. Girlie M. Millo, Supervising Science Research Specialist of DOST-MIRDC, alsopresented the capabilities of the MEIC being established in NEUST. The MEIC is envisioned tobe a venue for the conduct of more R&D project collaborations among the industry, the academe,and government agencies in the regions. For batch 2 of the project, Engr. Millo also mentioned that there will be additional 10 MEICs to be set up in the remaining regions of the country.

Engr. Millo presenting the MEIC project

“The metalworking industry will have access to advance machinery and equipment to help them“The metalworking industry will have access to advance machinery and equipment to help themdeliver their products and services as well as to produce food processing equipment andtechnologies developed by other research and development institutes (RDIs) through the MEICs,”assured Engr. Millo. She added, “the trained faculties and researchers of NEUST may be tappedas consultants by the industry, para hindi nyo na kailangan pa pumunta ng Manila or MIRDC forassistance.”

The DOST encouraged the industry to avail the services of the MEIC and to adopt theThe DOST encouraged the industry to avail the services of the MEIC and to adopt thetechnologies that are currently being developed by NEUST once they are complete. “Kung meronpa po kayong mga equipment and machines na gusto ninyong madevelop, pwede kayo makipagcollaborate sa NEUST-MEIC, MIRDC, and DOST-ROs,” said Mr. Mark John Ratio,Science Research Specialist II of DOST-PCIEERD.

Mr. Emmanuel S. Umali of Izzo Industrial Supply-Pampanga spoke on behalf of the industry andMr. Emmanuel S. Umali of Izzo Industrial Supply-Pampanga spoke on behalf of the industry andlisted its three main issues. The first issue is the scarcity of qualified machinists in the field.“Useless ang napakaraming makina kung wala namang operator,” Umali said. He added “yungiilan na graduate ay nagpupunta pa sa ibang bansa… walang laban ang mga local machine shopssa pa-sweldo ng abroad.”

The second issue he raised is that CNC machines are not currently practical in regional settingsThe second issue he raised is that CNC machines are not currently practical in regional settingsbecause of their high operational expenses. He suggested an alternative, such as a retrofitted orsemi-CNC machine.

Finally, he emphasized that one of the factors contributing to the low commercialization ofFinally, he emphasized that one of the factors contributing to the low commercialization ofdeveloped R&D innovations is the royalty fees. He stated “lagi kaming natatalo sa bidding dahilsa royalty fee, baka pwede naman ma-amend na kapag government project ay 1% nalang tomake it cost competitive.”

The process of conceptualizing for technology innovation is one of the primary struggles for smallThe process of conceptualizing for technology innovation is one of the primary struggles for smallbusinesses, according to Mr. Dennis Ruiz of PDMR Stainless Fabrication andGeneral Merchandise-Bulacan.

“…Nauubos din kasi ang oras namin sa pag-iisip palang, kaya di na namin naeentertain ang pag-“…Nauubos din kasi ang oras namin sa pag-iisip palang, kaya di na namin naeentertain ang pag-R&D dahil mas maghahabol nalang kami ng trabaho para makapag-generate ng income,” sharedby Mr. Ruiz.

Engr. Millo reminded the industry not to be intimidated to venture into research and development. She emphasized that an improvement to a single component or process may already qualify asan innovation. In this aspect, Engr. Millo stressed that the industry may collaborate with the MEICsand partner with other institutions to develop these ideas and concepts into new technologies.

The results of this consultation are anticipated to yield program developments that contribute to improving the M&E industry not only in Region III but across the country as well. The MEICs,along with other DOST initiatives, are intended to support the growth of innovation in the country.

More Skilled Trained Personnel for PEZA Locators' Requirements Seen

By Eldina B. Pinca

The Philippine Economic Zone Authority (PEZA) companies need a constant supply of skilled, well-trained workers.

This is one of the glaring facts discussed during the focus group discussion (FGD) held by the Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC) with PEZA-registered companies involved in the metals, engineering, and allied industries on November 29, 2022, at the Mold Technology Support Center (MTSC) facility in Gen. Trias, Cavite.

Atty. Norma B. Taňag, the Officer-in-Charge of the Office of the Deputy Director General for Operations of PEZA, commented that PEZA locators also experience some brain drain issues. Many PEZA companies have a high turnover rate of personnel.

Despite this, she shared that foreign investors still choose to locate their production plants in the Philippines. “Investors chose the Philippines as their permanent place of business because the Filipinos can be easily trained, and good designers,” according to Atty. Taňag.

Engr. Robert O. Dizon, MIRDC Executive Director stated that the MTSC, plus the DOST-MIRDC pool of trainers can assist in the professional and technical training of industry personnel. “Looking forward that many industry personnel will be trained well here at MTSC,” assured Executive Director Dizon.

Dr. Agustin M. Fudolig, MIRDC Deputy Executive Director, and the project leader of the MTSC was also delighted with the benefits that the MTSC may potentially offer the industry. He recalled that the DOST-MIRDC was able to produce 853 CNC trainees through a training program conducted in 2012-2014. Now, PDMA, Inc., in partnership with DOST-MIRDC, can utilize MTSC to train more workers and improve productivity for the benefit of the local metals industry and PEZA locators.

Also, Ms. Gilda S. De Jesus, Provincial Director of DOST-Cavite, shared her experiences with some of the local workers' capabilities. The local metal companies are able subcontractors that supply to Japanese companies in PEZA, and by word of mouth, also receive jobs from other Japanese locators. “These 100 percent Filipino-owned companies produce quality products and services which are also exported,” says Ms. De Jesus.

Mr. Julius A. Ontang, a former mold fabrication manager at PTON Corporation said he got tired of training new personnel because the moment they were already skilled, they look for a higher-paying job outside the company.

“We are hiring personnel without experience, and we train them first about the process andproduct and, if familiarized, they may work as production operators," stated Ms. Ria Rose Soriano, Admin General Manager of TOMS Manufacturing Corporation.

This pandemic has brought disruption to some local workers. Some chose to live with theirThis pandemic has brought disruption to some local workers. Some chose to live with theirfamily in their respective provinces, and others set up online businesses. This situation addsto the scarcity of skilled workers. Private and government training institutions should be ableto produce more skilled workers for the local metals industry. As the need for a steady poolof skilled workers is addressed, PEZA is assured to sustain its significant contribution forthe good of the Philippine economy.

Dr. Anthony Greg F. Alonzo presents the survey results in the FGD held at the MTSC facility inGen. Trias, Cavite.