DOST-MIRDC’s Initiative to Boost Capabilities of the Shipbuilding and Ship Repair Industry in Full Swing

By: Dr. Anthony Greg F. Alonzo, LPT

June 9, 2023

The series of consultative meetings with the shipbuilding and ship repair (SBSR) industry players continues as the industry study team of the Department of Science and Technology – Metals Industry Research and Development Center (DOST-MIRDC) will convene with the shipyards of the NCR on June 15, 2023, in Navotas.

In its continued pursuit to uplift the country’s metals, engineering, and allied industries, the DOST-MIRDC is conducting a study focused on the SBSR industry.

The first engagement of the team was with the SBSR industry players and stakeholders in Cebu in April. This was followed by a consultative meeting with the Zamboanga SBSR industry held on May 17, 2023, at the Zamboanga Peninsula Polytechnic University (ZPPSU).

Below are the highlights of the meeting with the Zamboanga SBSR players:

Mr. Kenji T. Olaso of Aleson Shipping said, “Zamboanga has a weaker SBSR industry compared to Cebu with regard to ship design.” Naval Architect Dan Bolanos of Frabelle Shipyard Corporation added, “Only licensed naval architects are allowed to design ships and there are only about 1,037 naval architects in the Philippines as of 2021, and many local shipyards in the Philippines rely only on AutoCAD for their design work.”

MIRDC delegates with SBSR players, academe officials, and government representatives during the SBSR Industry Dialogue held at the Dental Conference Room, ZPPSU

Engr. Jerry C. Cacacha did not agree with the statement that Zamboanga shipyards are weak, but rather “SBSR should know the basic principles of building ships and that workers are less exposed to SBSR industry trends.” He likewise shared that Filipinos lack ship design skills and students taking ship-related courses like welding will have better chances of improving their skills if they are given opportunities to experience on-the-job training in shipyards.

Moreover, he highlighted the need to determine and set standards for the metal composition of materials that will be most suitable for maritime use. According to him, this can be done through the collaboration of researchers, metal companies, and the government. This suggested R&D activity can potentially lead to the development and, ultimately, the availability of a highly rust-resistant metal despite constant exposure to seawater.

He also underlined the issue of the absence of a local steel mill, which will help meet the demands of the SBSR industry.

Dr. Josephine L. Sulasula, Vice President of Administration and Finance, mentioned that the current initiative that MIRDC is doing is very timely. She said, “We are planning to revive shipbuilding and ship repair courses in ZPPSU to produce a pool of workforce that will serve the SBSR industry.”

The active participation of the industry in the consultive meeting in Zamboanga mirrors how actively it is willing to support the DOST-MIRDC as the DOST-SBSR industry engagement continues to unfold.

Ships docked for scheduled repair and maintenance in Zamboanga City Daap Shipyard Incorporated

Presently, the DOST-MIRDC is in close coordination with the DOST-NCR, NCR shipyards, and the MARINA in preparation for the dialogue to be held in Navotas.

Looking ahead, the industry study team will visit more SBSR industry players in Regions III, VI, and XII. The Center is gearing up to determine the most appropriate science, technology, and innovation-based interventions for the SBSR industry through the consultative meetings and surveys that the industry study team is conducting at present.

Watch out for developments and updates about the industry study focusing on the SBSR industry by regularly visiting the DOST-MIRDC’s official website and fb page.

Title: Plastic Injection Molding Machine Operation

Date: June 13-15, 2023

Time: 8:00am to 5:00pm

Reservation Link: https://bit.ly/Res_Plast_Inj_Mold_Mach_June13-15_8-5pm

Title: Plastic Injection Mold Assembly

Date: May 22-24, 2023

Time: 9:00am - 4:00pm

Reservation Link: https://bit.ly/Res_Plas_injt_Mold_Assembly_May22-24_9-4pm

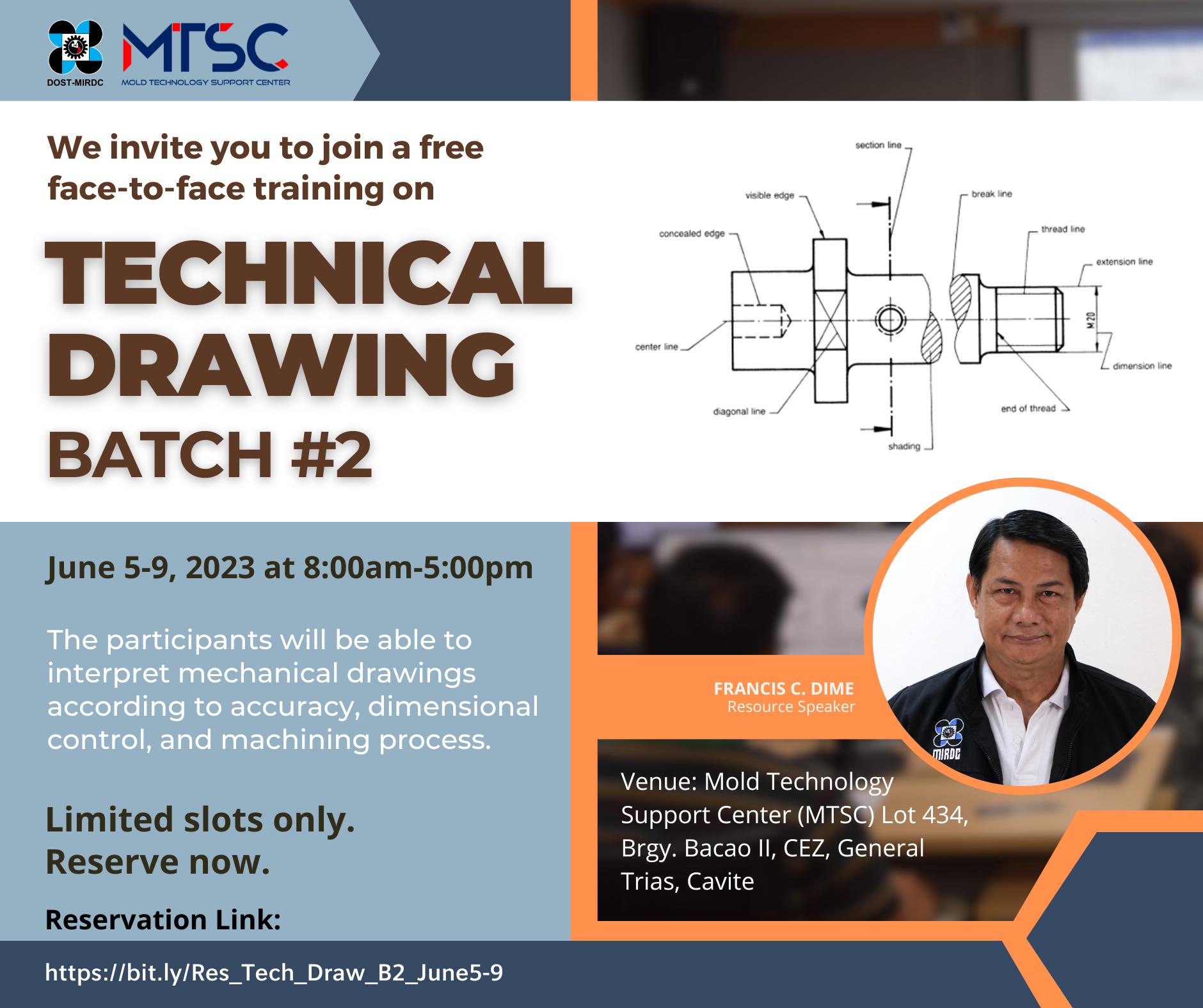

Title: Technical Drawing

Date: June 5-9, 2023

Time: 8:00am - 5:00pm

Reservation Link: https://bit.ly/Res_Tech_Draw_B2_June5-9

DOST-MIRDC Rolls Out Industry Study Focused on Assessing Science, Technology, and Innovation Needs of the PH Shipbuilding and Ship Repair Industry

By: Zalda R. Gayahan

May 10, 2023

The involvement of all essential stakeholders – the industry, academe, training institutions, and the government is a strategy that best defines the success of industry improvement initiatives.

By the looks of it, the industry study being implemented by the Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC) has started to earn the interest and involvement of the shipbuilding and ship repair (SBSR) industry players and stakeholders.

Ships docked along coastlines is a common site in the province of Cebu.

Considering that the Philippines has been the fourth largest ship producer in terms of gross tonnage since 2010 (DTI, 2017), the country must deal with the SBSR industry’s great potential and big challenges.

The DOST-MIRDC’s 2023 industry study assesses the present capabilities of the industry against a background of its very significant role in economy-building and its vast potential in better serving the requirements of the market.

In a dialogue conducted on April 19, 2023, at the Conference Room of the DOST VII in Lahug, Cebu City, representatives of SBSR industry players, from the Maritime Industry Authority (MARINA), Shipyard Association of the Philippines, and the academe generously provided insights about the status, requirements, and potential direction of the SBSR industry.

The dialogue with the SBSR industry players and stakeholders was conducted on April 19, 2023, by the DOST-MIRDC in partnership with the DOST VII.

The SBSR players themselves shared that the demand for ship repair is bigger than that for shipbuilding, but the industry ‘lacks support from the government,’ said one of the participants in the dialogue.

How do we deal with an industry that has so much potential, but says it lacks the support it needs?

From the industry players’ point of view, it is crucial that we define our focus first. It turned out that the biggest issue is building the industry’s capability and capacity to serve the requirements of the domestic market. The basic need, according to the players and stakeholders, is design.

The local SBSR builds ships, but the designs do not come from us. Apparently, the industry lacks software and hardware. The academe agrees with this, too.

Engr. Jacklyn Descartin, Chairperson of the Naval Architecture and Maritime Engineering at the University of Cebu Maritime Education and Training Center, acknowledged that the industry’s weakness lies in design because of the lack of both software and hardware in the training and educational facilities. She shared that the university has produced graduates who were taught manual drawing. But the university is catching up with the shift in technology: ‘From basic AutoCAD,’ she says, ‘the academe has improved capabilities for design. The problem is technology transfer.’

With technology transfer, Engr. Descartin refers to the capabilities of using the software, analyzing the results of the design, and determining options for dealing with design flaws.

Mr. Vincent Cavalida, Mr. James Verallo, and Mr. Noel Taliman, representatives from the MARINA, also agreed. According to them, the various software we use is acquired from other countries. When we purchase, we are given insufficient technological training.

Another point raised during the dialogue is not about the Filipinos’ lack of capability but the lack of certification and the dwindling of skilled human resources.

The weak capability for design, the need for certification, and decreasing skilled human resources are among the most immediate requirements that need to be addressed, based on the insights of the Cebu-based shipyards and SBRS industry stakeholders.

A typical day in a typical shipyard in Cebu.

Mr. Sky dela Torre of the Philippine Trigon Shipyard Corporation voiced out that the government should consider setting up a center for the SBSR that consolidates all the necessary assistance the industry needs - software, hardware, and technical assistance on how to approach common scenarios in the shipyard, among others. This SBSR center will address the basic and most crucial needs of the industry players and will provide a high-impact intervention to the industry.

‘This SBSR center will not require a huge space,’ says Mr. dela Torre. He further commented that the Philippine Shipyard Association can provide technical people, while the local government unit of Northern Cebu can donate the land or property.

While the DOST-MIRDC team carries out the 2023 industry study on the SBSR industry, a project proposal for another collaboration is being reviewed by our partners in the Republic of Korea.

The Mold Technology Support Center (MTSC) is an output of an ODA project that inspired an upcoming PH-Korea joint project for the SBSR industry.

Stemming from the success of the Mold Technology Support Center (MTSC), an Official Development Assistance (ODA) grant from the Republic of Korea, the project on capability-building in the SBSR industry is another partnership that may be implemented next.

The DOST-MIRDC is the sole government agency mandated to serve the requirements and assist the metals, engineering, and allied industries so that it achieves increased productivity and competitiveness. The industry study being carried out by the DOST-MIRDC not only serves to accomplish the Center’s targets related to information exchange services. The Center, with its close coordination with the Korean project partners, the SBSR industry players, the academe, and the DOST VII, will play a significant role in the building up of technical capabilities.

The success of the consultative meeting with the SBSR industry and its stakeholders in Cebu is the motivation behind the consultative meeting to be held in Zamboanga on May 17, 2023. The industry study team is presently corresponding with the DOST Regional Office IX.

The industry study being conducted by the DOST-MIRDC will pinpoint the science and technology needs of the SBSR industry players to define and establish the project framework so that the assistance from our Korean partners will be tailor fit to ensure that benefits will be felt, market needs will be addressed, and full industry potential for growth and productivity will be achieved.