| Title: | Plastic Injection Mold Assembly |

| Date: | November 23-26, 2021 |

| Time: | 9:00AM - 4:00PM |

| Description: | At the end of the course, the participants will be able to explain the fundamentals of plastic injection mold assembly and assemble two-plate and three-plate plastic injection mold assembly |

| Registration Link: | https://bit.ly/MIRDC_Reserveform_Plastic_Inj_Mold_Assembly |

| Ttile: | Value Analysis/Value Engineering (VA/VE) for Die and Mold Industry |

| Date: | November 17-19, 2021 |

| Time: | 8:00AM - 4:00PM |

| Description: | The participants will perform a simple VA/VE study on mold and die. Through this training, participants will be able to develop a way of thinking that will improve the relationship among three important elements: product, function, and cost. |

| Registration Link: | https://bit.ly/MIRDC_ReserveForm_VA_VE_Die_Mold_Industry |

| Title: | Introduction to Mold Design - Batch #3 |

| Date & Time: | November 16, 2021 - 9AM - 11AM |

| Description: | This webinar is designed to help participants understand design requirements and specifications in mold making. There will be a discussion on hand calculation in the design process of mold parts such as gates, runners, and other industrially applicable parts |

| Registration Link: | Click here to register for this FREE Webinar |

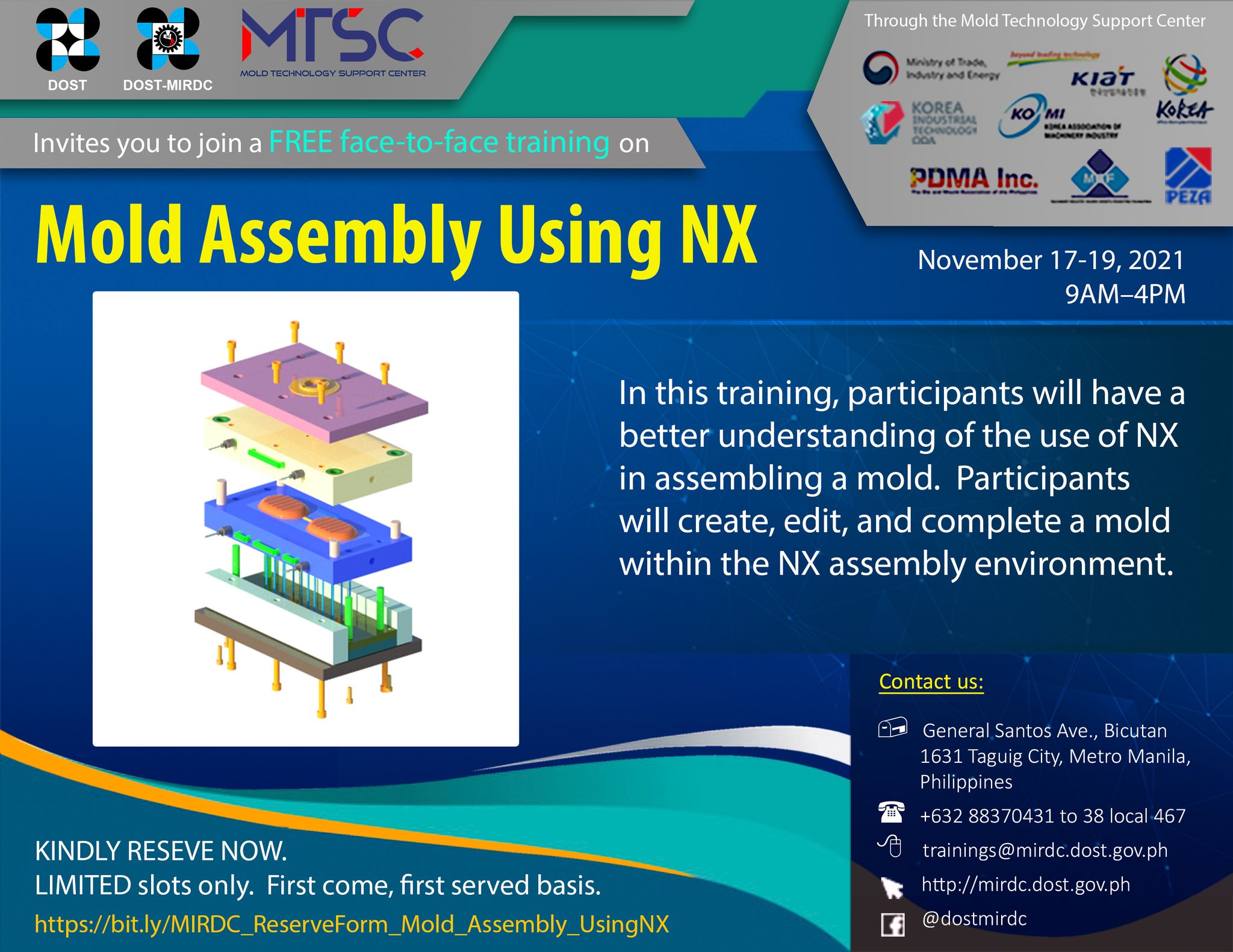

| Title: | Mold Assembly Using NX |

| Date: | Nov. 17-19, 2021 |

| Time: | 9:00AM - 4:00PM |

| Description: | In this training, participants will have a better understanding of the use of NX in assembling a mold. Participants will create, edit, and complete a mold within the NX assembly environment. |

| Registration Link: | https://bit.ly/MIRDC_ReserveForm_Mold_Assembly_UsingNX |

Click the link below to register for this FREE Face-to-Face Training