| Title: | Plastic Injection Molding Machine Process Batch #4 |

| Date: | October 29, 2021 |

| Time: | 1:00pm - 3:00pm |

| Registration Link: | https://bit.ly/Web_Regs_Plastic_Injection_Oct29_1-3pm |

| Description: | This training course is an introduction to the plastic injection machine operation. The learning content includes different types of injection machines, structures, and their significance |

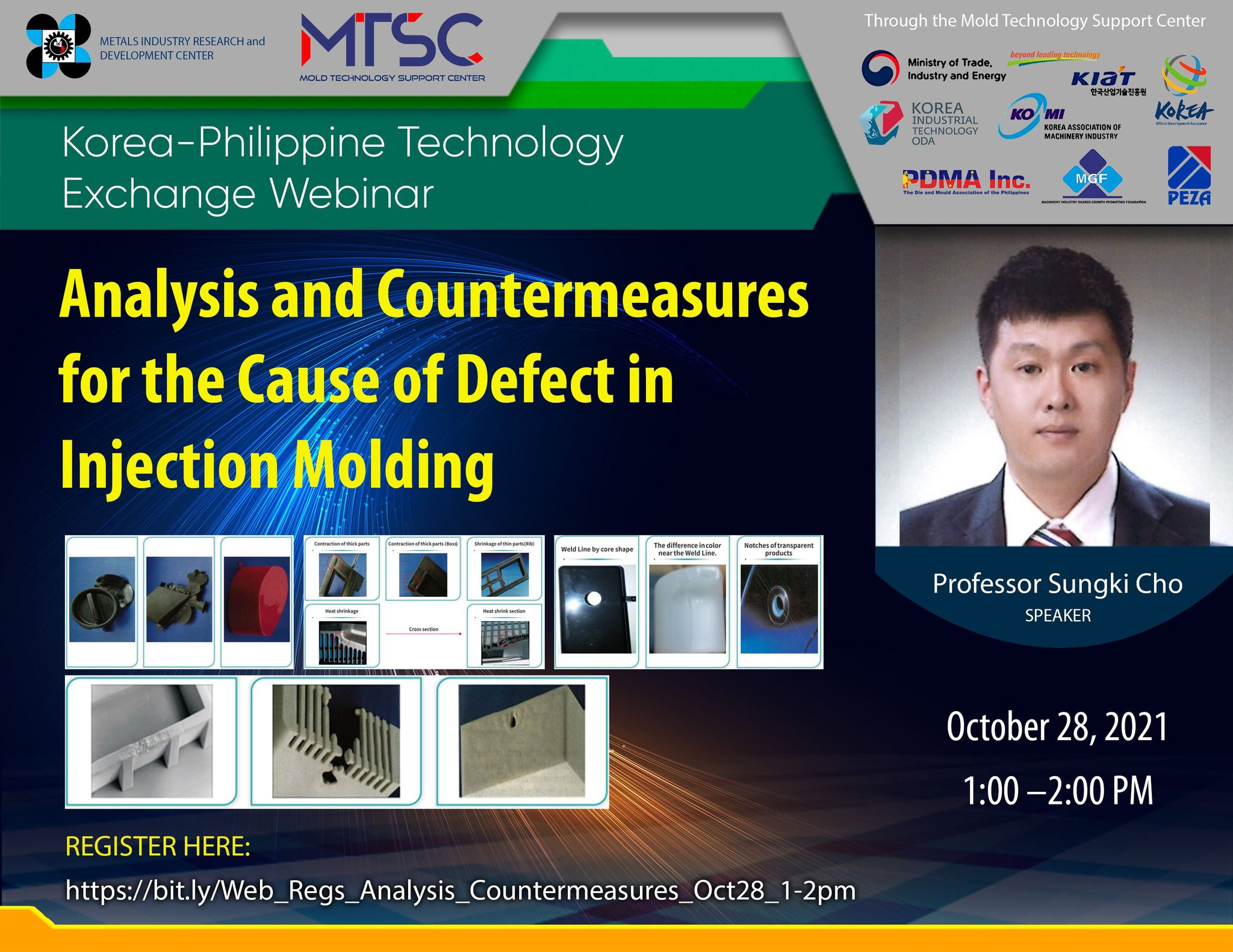

| Title: | Analysis and Countermeasures for the Cause of Defect in Injection Molding |

| Date: | October 28, 2021 |

| Time: | 1:00pm - 2:00pm |

| Registration Link: | https://bit.ly/Web_Regs_Analysis_Countermeasures_Oct28_1-2pm |

| Title: | Mold Assembly Batch #3 |

| Date: | October 21, 2021 |

| Time: | 1:00pm - 3:00pm |

| Description: | The webinar will help participants understand the mold assembly process and why the quality of mold assembly is important in manufacturing |

Register here using/clicking the link below:

https://bit.ly/Web_Regs_Mold_Assembly_Oct21_1-3pm

| Title: | Plastic Injection Mold Design |

| Date: | October 25-29, 2021 |

| Time: | 8:00AM - 5:00PM |

| Description: | At the end of the course, the participants will be able to explain injection molding process, mold designing, mold materials, perform mold designing and create 2D and 3D modeling using NX |

| Registration: | https://bit.ly/MIRDC_ReserveForm |

DOST Invites Electronics Industry to Avail Product Development Services

By: Zalda R. Gayahan

October 6, 2021 – Today, the Department of Science and Technology focuses on actively promoting its service offerings to the electronics industry through the conduct of the Online Kapihan entitled ‘DOST: Behind the Development of Competitive Electronics Products.’

The Electronics Product Development Center (EPDC) and the Advanced Manufacturing Center (AMCen) are two of the DOST's facilities that cater to the requirements of the electronics industry, from product conceptualization up to EMC and product safety testing.

The Orthopaedics International, Inc. (OII) and the Futuristic Aviation and Maritime Enterprise (FAME), partners of the EPDC and AMCen, discussed how their companies became involved in collaborative initiatives with the EPDC and the AMCen.

The OII is involved in the development of electronic medical devices. The trends in orthopedics include the use of instruments for better and more consistent placement and alignment of implants, and incorporation of electronics in instruments for better functionality, such as the use of a computer-assisted navigation system. ‘This puts pressure on our company to improve. We cannot just stay purely mechanical. We have to improve our instruments to take advantage of technology,’ says Engr. Jude L. Sasing, President of OII. ‘EPDC allows hobbyists to test ideas,’ he adds.

FAME, on the other hand, makes maritime transponders uplift the lives of fishermen. FAME's target market is small fishing vessels. FAME deploys transponders and trains fishermen how to use them. FAME collaborated with the AMCen for the 3D printing of transponder casing. ‘We made 3D printed samples…Right now we are filing an IP together with AMCen. We co-own that particular design. We are talking with the EPDC since we are enhancing the PBC design,’ shared Engr. Arcelio J. Fetizanan Jr, CEO of FAME. ‘Ang nakakatuwa dun is that we have everything created here in the Philippines, the design, the manufacturing, and even the testing,’ he further shared. ‘Nakaka-proud and thankfully DOST is there to support.’

|

|

|

(L) Engr. Sasing of Orthopaedics International Inc. and (R) Engr. Fetizanan of Futuristic Aviation and Maritime Enterprise (FAME) share their collaborations with the EPDC and the AMCen. |

|

The EPDC and the AMCEn offer their services to clients with the clients' convenience as a top priority. Both located within the compound of the DOST-MIRDC in Bicutan, Taguig City, the two facilities provide a one-stop solution to electronics products development and supports budding entrepreneurs, students, researchers, and MSMEs alike.

|

|

| The event emcee, Keith Dizon (R), with the panelists: (from L to R) Engr. Fred P. Liza, Program Leader of the AMCen; Engr. Joseph Alfred V. Garcia, Sr. Science Research Specialist of the DOST-MIRDC and AMCen; Engr. Julius T. Solomon, Head, EMC and Test Engineering Department of the EPDC, and Engr. John Ryan E. Gumtang, Head, Electronics Product Prototyping Department of the EPDC. |