High School Student Bested Industry Pros in National Welding Competition

By: Ella Vanesa L. Lopez

Bicutan, Taguig – Red A. Singin, a Grade 11 student from Rizal High School in Pasig City, emerged victorious in the Flux Cord Arc Welding (FCAW) in Carbon Steel (CS) Plate - 3G Position competition, despite competing against 13 seasoned industry professionals for the category.

From L to Right: Dr. Agustin Fudolig (MIRDC), Mr. Dominador Eleazar Jr. (PWS), Edralin C. Icabales (PWS), Ernesto Policarpio (PWS), Engr. Isidro Millo (PWS), Mr. Red Singin, Engr. Robert Dizon (MIRDC), Ms. Lina Afable (MIRDC),and Engr. Reynaldo dela Cruz Jr. (MIRDC)

Singin's welding skills and perseverance drove him to claim the championship. Reflecting on his unexpected win, he shared, "marami po mas may experience sa akin kaya ‘di ko inakala na ako ang magiging champion. "

Despite currently taking up Automotive in senior high school, Singin's triumph underscores his deep-rooted passion for welding. He also offered advice to aspiring young welders, urging them to “practice at focus sa goals lang po… manuod din po sila ng mga tutorials kung paano mag-welding para makadagdag din sa skills nila.”

Red A. Singin during the Welding Competition held last June 11, 2024.

The welding competition was part of the Metals and Engineering (M&E) Skills Competition, which was held to celebrate M&E Week every third week of June. The event included skills competitions in welding, robotics and mechatronics, and computer-aided design, intending to promote excellence in the metals and engineering industries.

The DOST-Metals Industry Research and Development Center (DOST-MIRDC), in collaboration with the Philippine Welding Society, Mechatronics and Robotics Society of the Philippines, and Philippine Die and Mold Association Inc., invited students, industry professionals, and other stakeholders from across the country to participate in this skills competition.

During the awarding ceremony on June 19, 2024, DOST-MIRDC Executive Director Robert O. Dizon emphasized the importance of using one's skills to contribute positively to the nation's progress, "Our country needs us. Sana unang makinabang ang ating bansa sa mga skills ninyo."

Guests and participants during the M&E Skills Competition Awarding Ceremony

The M&E Skills Competition is just one of the many activities lined up for M&E Week 2024, hosted by the DOST-MIRDC. For more details about the M&E Week 2024 and future events, please visit the DOST-MIRDC's official website and follow the official Facebook page.

DOST and DENR launched the Floating Solid Waste Collector System – A Filipino-made Technology to Solve Solid Waste Concerns

Manila, Philippines – Technology makes life easier, better, and more comfortable. Our country’s problem on floating solid wastes remains a major challenge for many years now, and various imported technologies have been tried to address this challenge.

This June, in the celebration of the Philippine Environment Month, the Department of Science and Technology (DOST) and the Department of Environment and Natural Resources (DENR) launched the Floating Solid Waste Collector System at the Pasig River Esplanade.

(T) One of the barges of the Floating Solid Waste Collector System and (B) key officials and representatives from DOST, DENR, and greater Manila LGUs present during the launching of Floating Solid Waste Collector System on June 13, 2024 at the Pasig River Esplanade.

The Floating Solid Waste Collector System represents a significant milestone in efforts to combat the challenges posed by solid waste and invasive water hyacinths in our rivers. DOST Secretary Renato U. Solidum, Jr. highlighted the benefits the technology will bring during his speech, “I am proud that this joint R&D project, the development of the floating solid waste collector, is one perfect example of a solution that not only address a challenge but also promises to open opportunities.” He emphasized that it will not only improve the environment but the fishermen’s productivity and provide livelihood not only to the fisherfolks but to the handicrafts and metal industry as well.

This innovative system is poised to address the persistent issues of solid waste and the overpopulation of water hyacinths in Metro Manila's waterways.

It features three essential components: a water hyacinth harvester, a dedicated trash collector, and a power barge for water hyacinth management. These components work synergistically to prevent flooding caused by clogged waterways, ensuring cleaner and more navigable bodies of water.

"The innovative solutions we have developed will not only help in the efficient removal and collection of floating solid wastes but also in preserving the ecological balance of our rivers and estuaries in Metro Manila... Let this project be a shining example of what we can accomplish when we unite for a common cause," said DENR- Environmental Management Bureau (EMB) Dir. Jacqueline A. Caancan,

The launch of this technology underscores the government's collaborative efforts in promoting sustainable environmental practices and innovative technological solutions. By integrating science and technology with environmental stewardship, the DOST and DENR are paving the way for a cleaner, more resilient Metro Manila.

“This Floating Solid Waste Collector System will breathe life and hope towards a greener future… The City of Manila, through the Department of Public Services whose mandate is ecological solid waste management and environment sanitation, is committed to promoting and upholding initiatives and interventions to nurture our environment" said Manila Mayor Maria Sheila Lacuna-Pangan on her hopes for a cleaner and greener environment.

Project Leader, Engr. Rodnel O. Tamayo, said that the prototype developed by the DOST will be subjected to performance testing in Cardona, Rizal. With optimism, the DOST and the DENR are certain that the system will be turned over to the DENR by the end of the year. Representatives from other local government units (LGUs) in the Greater Manila area were also present at the event, hoping that more LGUs would adopt this technology.

For more information, please visit DOST-Metals Industry Research and Development Center’s (MIRDC) official website https://mirdc.dost.gov.ph/ and Facebook page www.facebook.com/dostmirdc.

Drums are Beating in Preparation for the Metals and Engineering Week 2024

by Faith P. Macatangay

M&E Week 2024

The M&E Week is scheduled for June 18-21, 2024, in compliance with Presidential Proclamation No. 144, issued in 2011, which declared the third week of June as the Metals and Engineering Week. This yearly celebration is being held to acknowledge and appreciate the vital contribution of the metals, engineering, and allied industries to the economy’s dynamism.

This annual celebration, a tradition since 2009, offers numerous opportunities for learning and engagement. Key highlights for this year’s celebration include the M&E Industry Forum 2024 and the 3rd National M&E Conference, both set to take place at Hilton Manila on June 21, 2024. Other events include the M&E Skills Competition, an Open House at the DOST-MIRDC compound and Mold Technology Support Center (MTSC) in Cavite, and various free webinars.

Drumbeating M&E Week 2024

The Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC) held the M&E Week press conference to promote to the media the upcoming national celebration for the metals and engineering industry. Executive Director Robert O. Dizon emphasized the importance of media practitioners in disseminating credible and reliable information to the public, stating, "We rely on you to help us spread the good news that we have a metals and engineering industry that makes ways to make the economy more stable."

The event served as a platform for information exchange among industry associations, academic institutions, government agencies, and media representatives.

"Metals and Engineering Industry for a Brighter Tomorrow: Revitalized, Unyielding, and Sustainable"

Bannered by the theme, ‘Metals and Engineering Industry for a Brighter Tomorrow: Revitalized, Unyielding, and Sustainable,’ insights into the current market situation of the Philippine manufacturing industry were shared and discussed with the media. This was presented by Dr. Agustin M. Fudolig, Deputy Executive Director for Research and Development (R&D) and Chair of the M&E Week 2024 Committee. He underscored the critical role of the M&E industry in meeting the demands of various economic sectors and showcased the Center's R&D programs and specialized facilities designed to support local metals, engineering, and allied industries.

Industry representatives shared their latest technological advancements and initiatives aimed at driving innovation and contributing to the country's pursuit of a brighter future.

Industry partners expressed support for the upcoming M&E Week 2024 during the press conference at the DOST-MIRDC.

Updates, news, and other stories about the metals and engineering industry will unfold as the MIRDC spearheads the observance of the M&E Week 2024. More information about the industry and the upcoming event are available at the DOST-MIRDC website and FB page, as well as the visit the M&E Week website at www.metalsweek.dost.gov.ph.

Attendees from the media, DOST Media Core, industry, academe, and government during the M&E Week Press Conference at the DOST-MIRDC Compound, Taguig.

DOST offers aquaculture industry with a technology-based business solution

By Ella Vanesa L. Lopez

“Nakakatakot, dahil para sa amin malaking pera ang ii-invest, pero sa negosyo kailangan ay matapang ka… ako ay interesado talaga [sa i-POND], gusto ko ng malaking kita,” Beatriz Masangcay, a traditional shrimp farmer in Calapan City, Oriental Mindoro on the DOST-MIRDC’s iPOND technology during her visit to the Aqua Tierra Farm where the first i-POND prototype was installed.

DOST-MIRDC conducted a technology demonstration of i-POND in Aqua Tierra Farm, Oriental Mindoro on April 19-20, 2024 for farm owners, operators, and academe.

Traditional shrimp farmers rely on manual monitoring methods, such as visual observation or tools like thermometers, to assess water quality parameters. However, these conventional techniques are susceptible to human error and inconsistency, posing significant challenges for farm owners and operators.

The future of shrimp farming in the Philippines takes a significant leap forward with the introduction of the i-POND monitoring system developed by the Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC). The i-POND utilizes a long-range wide area network (LoRaWAN) technology to provide real-time monitoring of critical water quality parameters essential for shrimp survival.

With the i-POND, farmers can remotely monitor the water quality of their ponds using their smartphones or laptops, as long as an internet connection is available. This empowers the farmers to make informed decisions swiftly, enhancing operational efficiency, ensuring optimal conditions for shrimp growth and development, and assuring financial gains.

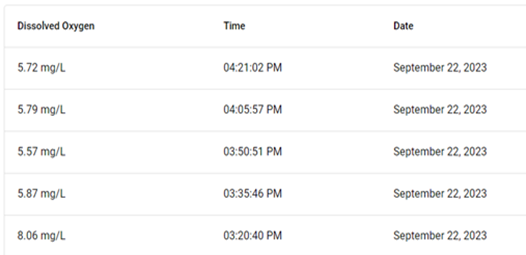

(T) i-POND prototype installed at Aqua Tierra Farm and (B) sample historical data collected by i-POND

Engr. Renato Gaudencio T. Goco, owner of Aqua Tierra Farm, expressed his enthusiasm for this technology, stating, "Ang kagandahan niyan [i-POND]… nate-test namin on real time kung may mga significant changes sa quality ng water… hindi na namin kailangan hintayin na may lumutang na hipon, makakapagrespond agad kami with corrective action." He also emphasized the convenience this technology has provided them in their day-to-day activities in the farm.

As shrimp farming continues to play a vital role in the economic landscape of the country, more farmers are starting to recognize the need to adopt modern solutions to enhance farm efficiency and financial returns. The integration of advanced monitoring solutions like i-POND reflects DOST-MIRDC's commitment to empowering farmers with the tools and technologies they need to succeed and foster growth in the aquaculture industry.

For more information on how DOST-MIRDC may help your businesses, you may send us an email at This email address is being protected from spambots. You need JavaScript enabled to view it. or message us on Facebook at dostmirdc.