DOST, DENR’s Solution to Collection of Solid Wastes in Rivers Gains Congressman’s Support

by Kai H. Negado

“Makakaasa po kayo, maglalaan po tayo ng pondo dahil isa ‘yan sa mga pinangako namin ni Mayor - na hahanapan namin ng solusyon ‘yung water hyacinths,” Congressman Emigdio Tanjuatco III after witnessing the collector system in action during its demo run held at Cardona, Rizal on 14 November 2024.

Rep. Emigdio Tanjuatco III, 2nd District of Rizal delivering his message during the Floating Solid Waste Collector System demo run in Cardona, Rizal.

Launched in June 2024 at the Pasig River Esplanade during the Philippine Environment Month celebration, the Floating Solid Waste Collector System is seen to address problems with clogged waterways caused by solid wastes.

Developed by the DOST-Metals Industry Research and Development (DOST-MIRDC) in partnership with the DENR-Environmental Management Bureau NCR (DENR-EMB NCR), this technology will not only improve the environment but also provide livelihood opportunities to fisherfolk and producers of usable materials and products from water hyacinths.

Project Leader Engr. Rodnel O. Tamayo of DOST-MIRDC presented the technology’s specifications, emphasizing its efficiency in harvesting 8 cubic feet of waste within 1.5 to 2 minutes at one full capacity of operation. He also mentioned that before the project ends, the prototype will be turned over to the DENR-EMB. The EMB will then turn it over to a local government unit in the National Capital Region that they will identify in the coming weeks.

A few more weeks to go before the said turnover of the collector system prototype, Cardona Mayor Bernardo San Juan, Jr. and Congressman Tanjuatco requested that the team clears Cardona’s side of Laguna Lake of water hyacinth and solid trash. Following the harvester technology’s impressive performance in the demo run, the project team readily agreed and gave their commitment to harvest the water hyacinth in December 2024.

The Floating Solid Waste Collector System in action during the demo run on 14 November 2024 at Cardona, Rizal.

With the demo run successfully showing that the locally designed and developed floating solid waster collector system indeed works and meets expectations, and with the commitment of support from Congressman Tanjuatco, communities along coastal areas and equipment fabrication businesses can look forward to the technology’s meaningful technology transfer and commercialization journey.

For more information and updates about DOST-MIRDC’s technologies, visit our official website https://mirdc.dost.gov.ph/ and Facebook page www.facebook.com/dostmirdc. For partnership opportunities on R&D, send an official request through email at This email address is being protected from spambots. You need JavaScript enabled to view it..

DOST-MIRDC Celebrates the MTSC’s Anniversary through Free Training for Die and Mold Industry

by Kai H. Negado

Despite nearly 2.4 million unemployed Filipinos, the demand for skilled workers remains high, particularly in the die and mold industry. The Department of Science and Technology - Metals Industry Research and Development Center (DOST-MIRDC), through its Mold Technology Support Center (MTSC), is trying to address this gap with targeted training and development initiatives.

In celebration of its anniversary, the MTSC conducts free training programs to give skilled workers in the die and mold industry an exceptional chance to upskill or reskill. The free face-to-face training programs are as follows:

- Basic Technical Drawing

- Advanced Technical Drawing

- Mold Design

- Injection Mold Assembly

- Injection Machine Operation

The training programs will run for one week, beginning today, November 4, until Friday, November 8, 2024, at the Mold Technology Support Center, Pacific Avelex Realty Corp., Lot 434, Brgy. Bacao II, CEZ, Gen. Trias, Cavite.

Engr. Vengua and Mr. Musnit as instructors during the free MTSC training

Engr. Sy of the MTSC and the attendees during the free MTSC training

DOST-MIRDC Executive Director Robert O. Dizon congratulates the MTSC on its significant milestone, stating that “this facility has been one of the DOST-MIRDC’s latest offerings to the metals and engineering industry where we address the innovation needs of local die and mold companies. It is exciting to see all of us working together to achieve a common goal.”

DOST-MIRDC also welcomes collaborations with companies in the metals and engineering industries interested in upskilling their workforce through the Center’s regular and tailored training programs. For more information, please visit our website at mirdc.dost.gov.ph, follow us on Facebook (@dostmirdc), or contact us via email at This email address is being protected from spambots. You need JavaScript enabled to view it..

This anniversary event underscores DOST-MIRDC’s ongoing commitment to strengthening the Philippine workforce and supporting the local die and mold industry.

Challenges of the Philippine Metal Casting Industry: Metal Casting Companies Up Close and Personal with DOST-MIRDC

By James Bernard Herrera

The metal casting industry is said to be a cornerstone of manufacturing industries worldwide. It is involved in the various sectors that make a country’s economy thrive, such as agriculture, transportation, and defense sectors. However, in the Philippines, the metal casting industry has been experiencing a constant decline over the last few decades, which directs us to this question: what are the causes of this decline?

The Department of Science and Technology - Metals Industry Research and Development Center (DOST-MIRDC) gathered local metal casting companies for a focus group discussion (FGD) on September 23, 2024, at La Breza Hotel, Quezon City. The event was part of the Center’s industry study titled “Local Metal Casting Industry Thriving Despite Challenges,” to verify the study’s findings as it nears completion.

The study focuses on why the metal casting industry, once robust, has become a declining industry in the Philippines. From hundreds of local foundries operating in the 1970s, the number has dwindled to just 68 foundries.

During the FGD, the team presented the study findings, where participants also provided feedback and verification.

Industry players showing keen interest in the findings being presented by Ms. Kathlyn Kai Negado.

Money factor. The first and most pressing challenge identified was financial. Many companies have experienced a shrinking market share, which they attributed largely to the influx of imported cast products. As one participant noted, “The local market is not just being penetrated by imports, it’s already dominated by them.”

Machine and method factors. The financial strain also ties into the challenges around machines and methods. Many companies are reluctant to invest in modern technology, fearing that the uncertain market demand will not justify the cost. Most foundries now operate on a jobbing basis, which makes investing in technology and capability upgrades too risky a business move. One participant shared their company’s first-hand experience: one of their customers opted to import metal cast products rather than commission their foundry for production.

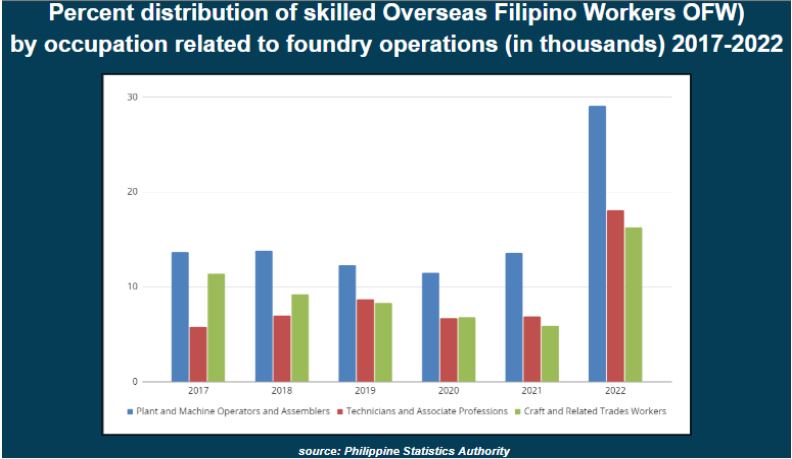

Manpower factor. The next major challenge is manpower. The metal casting industry has been grappling with brain drain for over a decade. Data from the Philippine Statistics Authority (PSA) shows that thousands of skilled workers in related fields have gone abroad, leaving a significant shortage of talent in the local industry.

Many companies have been forced to recruit and train workers with no prior knowledge or experience. Some participants confirmed this statement and even mentioned that they actively search for potential employees in provincial areas, as many urban-based young workers view foundry jobs as “dirty and unappealing”—a sentiment widely echoed during the discussion.

Materials factor. Material sourcing also presents a challenge. Most local foundries rely on imported raw materials, such as silica sand and foundry coke. The import taxes on these materials lead to increased production costs, forcing companies to raise their prices to remain viable, further hindering the industry's marketability.

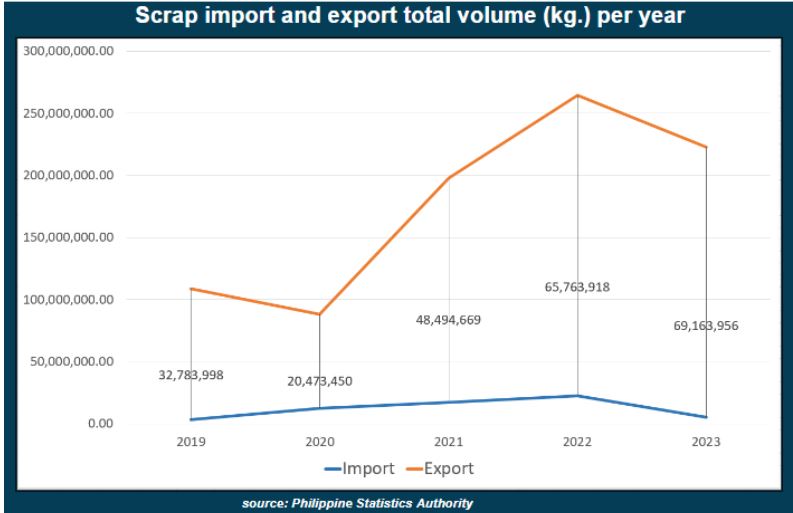

Aside from these imported materials, procuring locally-available scrap is also part of the challenge due to its price being unregulated at present by any government entity. It is also discussed that the Philippines exports high volumes of scrap material in kilograms over the last five years, where Bangladesh is found to be the top client. During the discussion, industry players mentioned that the price of local scrap is currently being dictated by the purchasing rates of steel companies, making the price of scrap metal very erratic within the local market.

As the FGD wrapped up, Industry Consultant Engr. Napoleon Tanganco expressed optimism: “I believe the current number of existing companies will stabilize, as most of the remaining ones are large enterprises.” However, while larger companies may continue to survive, smaller ones will likely continue to struggle unless significant changes are made. This is where DOST-MIRDC’s role becomes crucial. The study team gathered additional feedback during the FGD, which will be incorporated into the industry study.

Engr. Napoleon Tanganco sharing his insights during the discussion

Moving forward, the study team will consult with DOST-MIRDC experts and management to finalize recommendations. The goal is to revitalize the local metal casting industry and significantly contribute to the country’s economic development. The study’s findings and recommendations are scheduled to be presented to the Center’s officials and Governing Council by the end of 2024.

DOST powers CALABARZON with R&D and Manufacturing Capabilities at Batangas State University

By: Ella Vanesa L. Lopez

Malvar, Batangas – October 7, 2024 – In a strategic move to enhance local manufacturing capabilities, the Department of Science and Technology (DOST) officially inaugurated the Metals and Engineering Innovation Center (MEIC) at Batangas State University (BatStateU) Malvar Campus today. Primarily, this center aims to empower industries and academe in the CALABARZON region with advanced metalworking technologies and research and development (R&D) support.

(T) DOST officials’ ribbon cutting and (B) unveiling of MEIC-BatStateU marker

Top photo, From L to R: BatStateU Malvar Chancellor, Dr. Amado C. Gequinto, DOST CALABARZON RD Emelita Bagsit, BatStateU Pres. Tirso A. Ronquillo, DOST Sec. Renato U. Solidum, DOST USec Leah J. Buendia, and DOST-MIRDC Exec Dir. Robert O. Dizon

DOST Secretary Renato U. Solidum Jr. described the MEIC as a crucial asset for local agricultural machinery fabrication, underscoring its potential to reduce the Philippines' dependence on imported equipment. “Isa sa ating tinitingnan na kailangan natin palakasin ay ang fabrication ng agricultural machineries na kinakailangan natin upang ma-mechanize ang ating agricultural sector. Instead of importing foreign machinery, kayang-kaya na 'yan ng mga Pilipino,” Secretary Solidum asserted.

DOST-MIRDC Executive Director Robert O. Dizon shared that the initiative, originally envisioned to establish three MIRDC satellite offices across Luzon, Visayas, and Mindanao, has since grown, with five MEICs now operational and 10 more in development.

The MEIC, often referred to as a "mini-MIRDC," is equipped with approximately PHP 10 million worth of industrial-grade machinery, providing facilities for designing and fabricating machines and metal components. This setup will allow researchers to develop practical R&D outputs, which local fabricators can then commercialize, enhancing efficiency in the industry.

Highlighting the significance of innovation, DOST Undersecretary for R&D Dr. Leah J. Buendia noted the center's potential to drive growth in the renowned coffee industry of Batangas and other agri-processing sectors. “Innovation begins by identifying problems and turning ideas into tangible solutions, and now you have the tools to make that happen,” she stated.

Some of the machineries installed at MEIC-BatStateU

Top to Bottom: Hydraulic Shearing Machine, Rolling Machine, Hydraulic Press Brake, and Plasma Cutting Machine

The MEIC will also serve as a training hub for students, researchers, and industry professionals, providing hands-on experience and exposure to cutting-edge technologies in metalworking. This initiative aims to bridge the skills gap in the engineering sector and equip future professionals with practical competencies.

BatStateU President Dr. Tirso A. Ronquillo expressed optimism about the center's role in enhancing their academic programs. “The MEIC is a very critical supplement to our offered engineering and technology programs,” he said.

Strategically located in Malvar, BatStateU, through MEIC, aims to attract investors and foster collaborations in the region, by leveraging Malvar’s growing industries and prime location. The center is expected to drive economic growth by promoting partnerships among industry, academe, and government, particularly focusing on supporting micro, small, and medium enterprises (MSMEs).

The establishment of the MEIC is part of a nationwide initiative by DOST to create innovation centers in key regions across the Philippines. With five centers already operational in Regions I, II, III, CAR, and X, the MEIC at Batangas State University is part of the second batch, with full operational status expected by 2026.

DOST-MIRDC Committed to Make its Presence Felt in Region II through MEIC-CSU

By: Zalda R. Gayahan

Not every day, a state university receives assistance from a government agency. On September 25, 2024, the bright skies and the clear weather lay witness to another milestone of the Department of Science and Technology – Metals Industry Research and Development Center (DOST-MIRDC). It was on this day that the DOST-MIRDC was able to strengthen its pursuit of establishing mini-MIRDCs in the region – through turning over the Metals and Engineering Innovation Center (MEIC) to the Cagayan State University.

Key officials of the DOST, DOST-MIRDC, and CSU were present during the event to celebrate the collaboration that resulted in the establishment of a facility that will catalyze the innovativeness of metals, engineering, and allied industries in the region – the MEIC.

DOST Secretary Renato U. Solidum leads officials in the unveiling of the MEIC-CSU marker during the handover ceremony on September 25, 2024 held at the CSU Carig Campus.

DOST-MIRDC Executive Director shared how the MEIC concept began with instructions from the former DOST Undersecretary for R&D, Dr. Rowena L. Guevara. According to Director Dizon, Usec Guevara brought forward the idea of putting up metals innovation centers in all regions. This idea was then supported by former DOST Secretary Fortunato T. dela Peña. Dir. Dizon further shared that the framework included coordination with DOST Regional Offices who were given the role of nominating a state university where the MEIC will be located. DOST Regional Office II was among the first five regional offices that nominated an SUC, which is the very proactive and supportive CSU

DOST-MIRDC Executive Director Engr. Robert O. Dizon shares the story of the MEIC during the handover ceremony of the MEC-CSU.

Dr. Marilen V. Cauilan, opens the handover ceremony of the MEIC-CSU on September 25, 2024.

President for Academic Affairs of the CSU said, ‘We are really so thankful to DOST. There are many areas of collaboration we have with DOST. We hope to have more collaborations.’ Dr. Cauilan further suggested that the CSU and DOST collaborations can continue to make significant contributions to the global community through strengthening local brands.

The MEIC in CSU is part of the first batch of the MEIC project whose implementation started on August 1, 2021. MEIC batch 1 was completed on July 31, 2023.

Usec. Leah J.Buendia addresses the guests during the handover ceremony.

USec Leah J. Buendia, DOST Undersecretary for Research and Development, also gave her support to the handover ceremony. ‘We are all proud to witness that the results of R&D will be used by and transferred to CSU. This is one of the visions of Secretary Solidum – to roll out our R&D results not only to researchers but also to adopters,’ Usec. Buendia remarked.

DOST envisions the achievement of national development through science, technology, and innovation. Supporting the DOST in the realization of this vision are its seven attached research and development institutes, one of which is the DOST-MIRDC.

The rollout of the R&D results to adopters, Usec. Buendia said, ‘is DOST’s commitment in the next four years.’

Usec. Sancho A. Mabborang, Undersecretary for Regional Operations, urges the audience to keep on innovating.

Usec Sancho A. Mabborang, Undersecretary for Regional Operations, warmly welcomed all guests to the turnover ceremony and urged everyone to keep reaching for goals. In his message, Usec Mabborang said, ‘We have made significant steps toward the realization of aspirations. We are moving forward. Ituloy-tuloy po natin ang trabaho. We need to keep innovating. We need to keep aspiring.’

By aspirations, Usec. Mabborang was referring to DOST and MIRDC’s aspirations of utilizing science, technology, and innovation to achieve national development. Usec. Mabborang also mentioned the Electromobility Research and Development Center (EMRDC), similar to the MEIC, one of the newest facilities that make the CSU’s portfolio of technologies more complete and competitive. According to Usec. Mabborang, the MEIC, EMRDC, and CSU should work together and continue to innovate to contribute to the growth of the country’s economy.

Making the economy grow is a vision shared by all, especially by DOST Secretary Renato U. Solidum. He expressed his hope that the MEIC-CSU will make a lot of products. Sec. Solidum reminded everyone: ‘To whom much is given, much is expected.’ This quote, according to him, is a perfect reminder for the why the EMRDC and the MEIC are facilities established at the CSU. ‘I hope that we can show to the public that this (EMRDC and MEIC) is the way to go for sustainability efforts and to make sure that our environment is clean,’ Sec. Solidum shared. ‘Bottom line is we really want to make sure that our R&D contributes to our economy.’

DOST Secretary Renato U. Solidum Jr. expresses his hopes that DOST, MIRDC, and CSU contribute to the economy through R&D.

After the initial program, DOST and CSU officials conducted a brief tour of the CSU campus to visit the Food Innovation Center, EMRDC, and hold the unveiling of the MEIC marker.

DOST-MIRDC provided various equipment to complete the establishment of the MEIC, including a hydraulic shearing machine, power hacksaw, sheet metal roller, hydraulic press brake, workstation with CAD/CAE software, and various electric and hand tools, among others.

Some of the equipment installed at the MEIC-CSU intended to encourage the industry and academe to engage in R&D.

The handover ceremony is one milestone for the DOST, DOST-MIRDC, and the CSU as the MEIC will continue to serve as a facility for R&D, consultancy and technology transfer collaborations with metals and engineering companies, universities, and other potential users. Being a technology hub for the regions, especially for the metals and engineering firms, DOST-MIRDC will now be able to extend its services to more industry players in the countryside.