Advanced Manufacturing Center (AMCen) Encourages Businesses and Academe in Region IX to Innovate Using Additive Manufacturing

Kai H. Negado

“Additive Manufacturing (AM) is a bridge between imagination and reality,” was how AM was described by Mr. Aris Mortalla of DOST Region IX. As a 3D printing hobbyist, Mr. Mortalla shared his personal view on AM or 3D printing, and how it may be utilized by their stakeholders in the Zamboanga Peninsula region.

AM stands as one of the pioneering Industry 4.0 technologies offered by the Department of Science and Technology (DOST) through the DOST-Metals Industry Research and Development Center (DOST-MIRDC). The establishment of the Advanced Manufacturing Center (AMCen) has seen outputs from various collaborative research and has already manufactured AM products that are being used by its partners. AMCen extends its services not only to domestic manufacturers but also to micro, small, and medium enterprises (MSMEs) across diverse sectors and educational institutions alike.

Driven to make this technology hub and its services known to the public in different regions of the country, DOST-MIRDC features AMCen as one of its offerings in the celebration of the Regional Science, Technology, and Innovation Week (RSTIW) 2023.

DOST-MIRDC is currently participating in DOST IX’s RSTIW celebration in Zamboanga Peninsula.

Engr. Alvin Buison, Senior Science Research Specialist at DOST-MIRDC and a key member of the AMCen project, emphasized during his presentation that AM can be seamlessly integrated into traditional manufacturing processes, “AM is a tool para makatulong sa conventional manufacturing - incorporate it (AM), to help.” He underscored that AM serves as a supplementary tool to enhance conventional manufacturing practices. Its unique capabilities, such as lightweighting features – lattices and topology-optimized geometries, address the needs of industries such as aerospace and automotive, as well as capitalize on the use of fewer materials without sacrificing a product’s quality.

Engr. Alvin Buison of AMCen, DOST-MIRDC during the forum on AM at Dapitan City, Zamboanga del Norte.

AM is poised to become a catalyst for innovation and community development in Zamboanga. Engr. Buison encouraged attendees to explore innovative applications of AM in their daily lives and local communities.

For businesses, AM technologies offer a cost-effective means of product development. This translates to reduced capital investments and accelerated prototype development, enabling businesses to iterate their products swiftly. Educational institutions benefit as well, with AMCen offering a range of training programs focused on AM technologies and design. This equips the next generation of engineers with essential knowledge of AM technologies.

The forum conducted by the AMCen on Sept. 7, 2023, at the Amphitheater, Dapitan City Hall, Dapitan City, opened opportunities for possible future collaborations between the DOST Regional Offices, academe, and industry. This is also part of AMCen’s efforts in bringing Industry 4.0 technologies closer to communities in the regions.

Watch out for more DOST-MIRDC activities in the regions, including exhibits and fora in the upcoming RSTIW celebrations around the country.

For more information on the Center’s available technologies and services, interested parties may contact the DOST-MIRDC through This email address is being protected from spambots. You need JavaScript enabled to view it.. For updates, follow our official Facebook page dostmirdc, and visit our website at mirdc.dost.gov.ph.

Title: Mold Wizard Design Process

Date: September 12-14, 2023

Time: 9:00am - 4:00pm

Reservation Link: https://bit.ly/Res_Mold_Wiz_Des_Process_Sept12-14_9-4pm

Enhancing Opportunities: Launch of the Advanced Welding Training Center (AWTC) to Empower Future Welders

By Kai H. Negado

“Kailangan makapag-produce tayo ng higher paying jobs… at least makapag-tayo ng business yung makaka-graduate dito sa ating training program,” Engr. Gerald Gallardo, a driving force behind this visionary project and Rotary Club of Mandaluyong Central (RCMC) Project Head, gives us a glimpse of how the Advanced Welding Training Center (AWTC) will help chart the future of workers highly skilled in the field of advanced welding and entice professional welders to become successful entrepreneurs as well.

Held at the DOST Metals Industry Research and Development Center (DOST-MIRDC) on August 11, 2023, the ceremonial signing of the Memorandum of Agreement (MOA) on the establishment of the AWTC between the RCMC, the Philippine Welding Society (PWS), Inc., and the DOST-MIRDC, marks the beginning of another science, technology, and innovation-based intervention that will address the need for more training offerings on advanced welding processes.

Standing (from L to R): Ms. Irene Gallardo, President, RCMC; Engr. Jonathan Q. Puerto, Deputy Exec. Dir. for Technical Services, DOST-MIRDC; and Engr. Isidro Millo, Interim President, PWS Inc. Seated (from L to R): Engr. Gerald S. Gallardo, RCMC Project Head; Engr. Robert O. Dizon, Exec. Dir., DOST-MIRDC; and Mr. Dominador C. Eleazar, Jr, Exec. Dir., PWS, Inc.

During his congratulatory message, Atty. Clefford Pascual, Chief, Partnership and Incentives Assistance Division, who attended as a representative of the Technical Education and Skills Development Authority (TESDA), underlined the AWTC's pivotal role in shaping both our workforce and the economy. Pascual aptly stated, “the establishment of the AWTC is not just an investment in education and training, but an investment for the industry and in the future of our Filipino brothers and sisters who will benefit from this collaboration.”

The AWTC is poised to amplify the welding proficiency of the Filipino workforce, catering to the increasing demands for skilled welders both within the country and abroad.

Engr. Reynaldo L. Dela Cruz, Chief, Industrial Training Section of DOST-MIRDC and Board Member of the PWS, Inc. emphasized on how the welding sector contributes to various industries, “kahit ospital, basta may maintenance, may welding.” He also enumerated the different major industries where welding is a crucial metalworking process, such as manufacturing, power generation, refinery, transportation, aerospace, food, agriculture, construction, and mining.

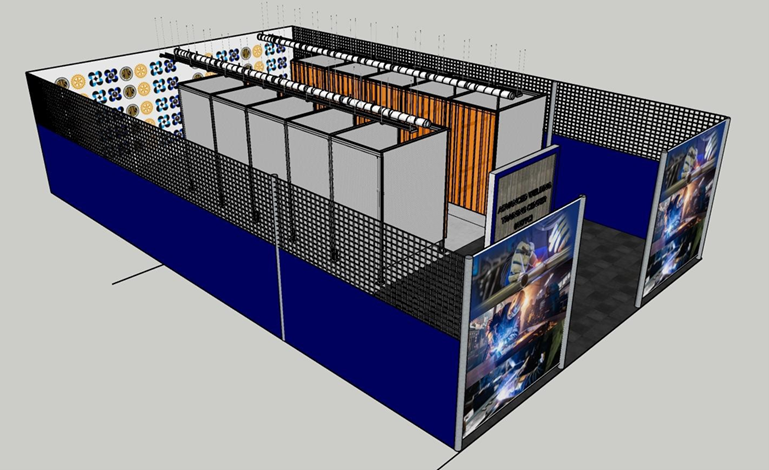

The DOST-MIRDC will house the facility in its compound, design its training programs, and manage its operations along with PWS, Inc. The completion of the AWTC facilities is anticipated by the end of 2023.

Proposed layout of the Advanced Welding Training Center (AWTC).

For updates and comprehensive insights into the AWTC's establishment and other services provided by the DOST-MIRDC, please visit the official DOST-MIRDC Facebook page and website at www.mirdc.dost.gov.ph.

Title: Mold Assembly Using NX

Date: August 29-31, 2023

Time: 9:00am - 4:00pm

Reservation Link: https://bit.ly/Res_Mold_Assembly_NX_Aug29-31_9-4pm